SERVICE

Material Testing (FRPs)

Mechanical Testing

Continuously innovating and evolving.

Full-Service of Composite

In order to be a globally leading company in the composite evaluation field, Kiguchi provides total support that covers everything from basic property evaluation to fracture testing. For instance, we can perform conditioning before testing such as moisture absorption, and evaluation after immersion in special solvents such as jet fuels and aircraft fuselage cleaning agents. Moreover, we have the high-speed camera capable of reaching up to 1 Million frames per second and visualizing the origin of fracture.

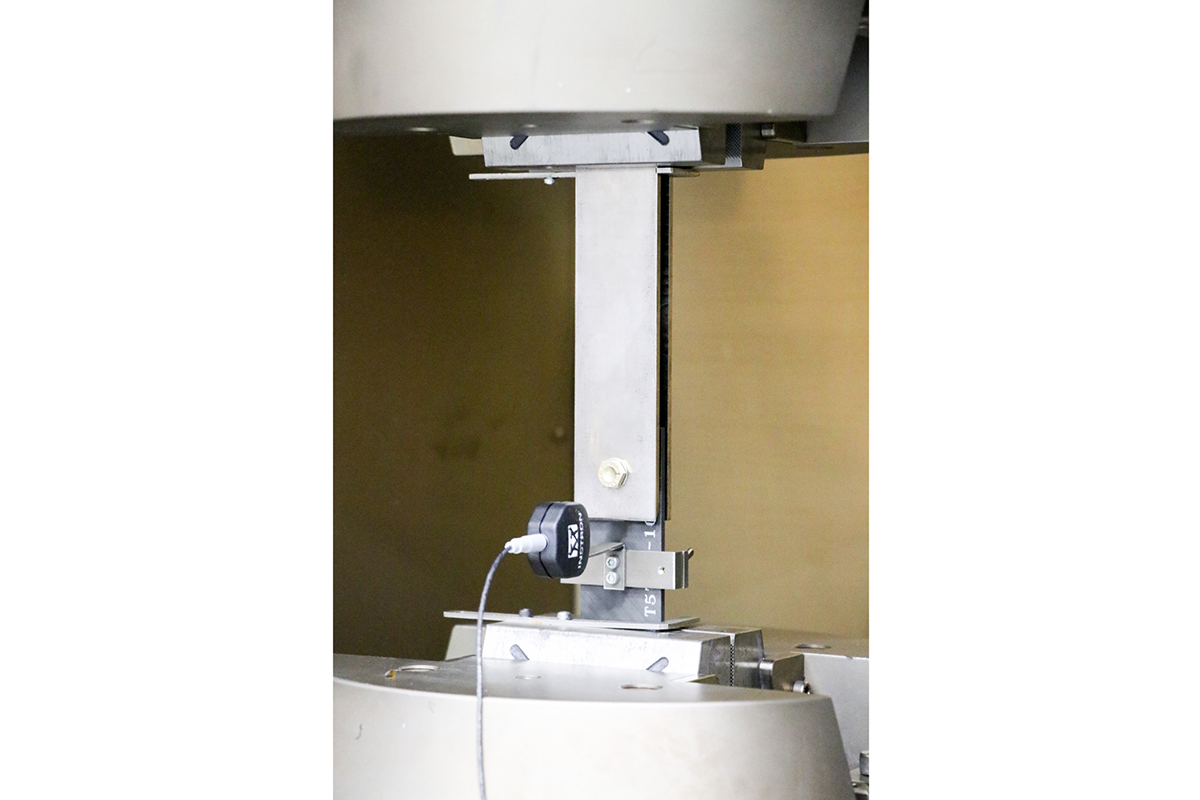

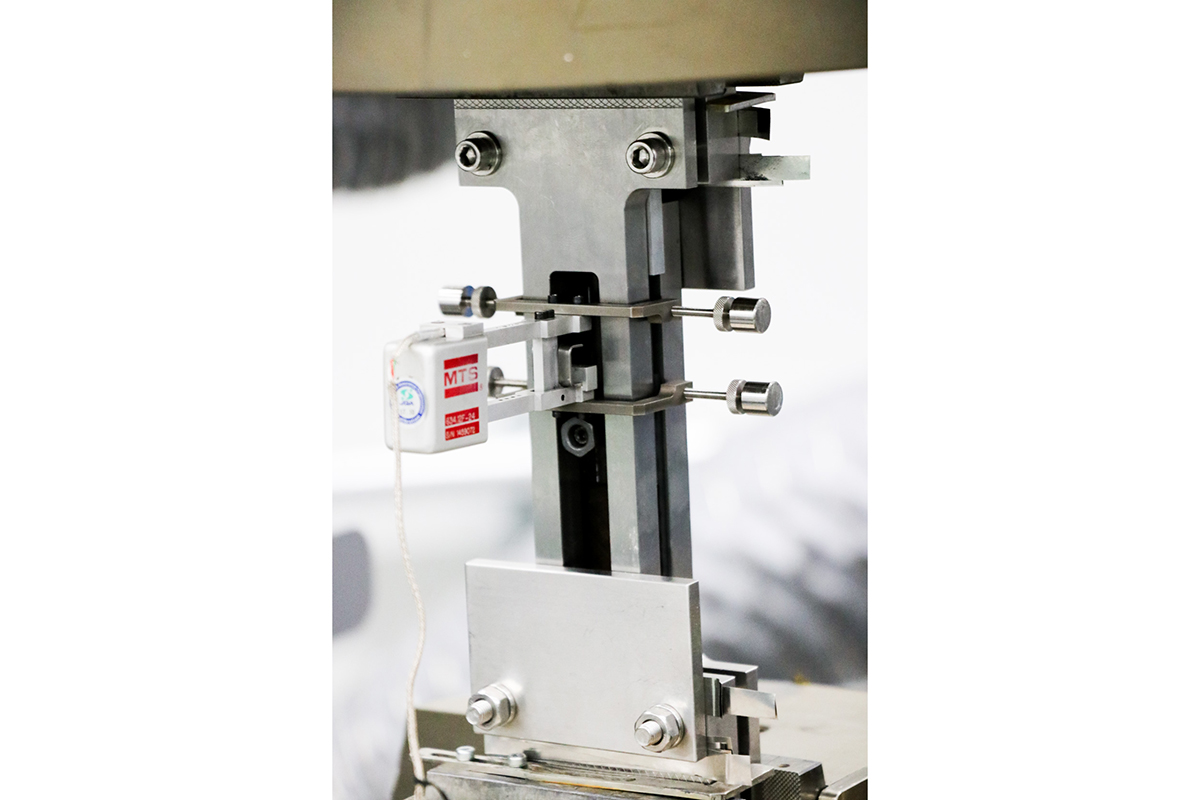

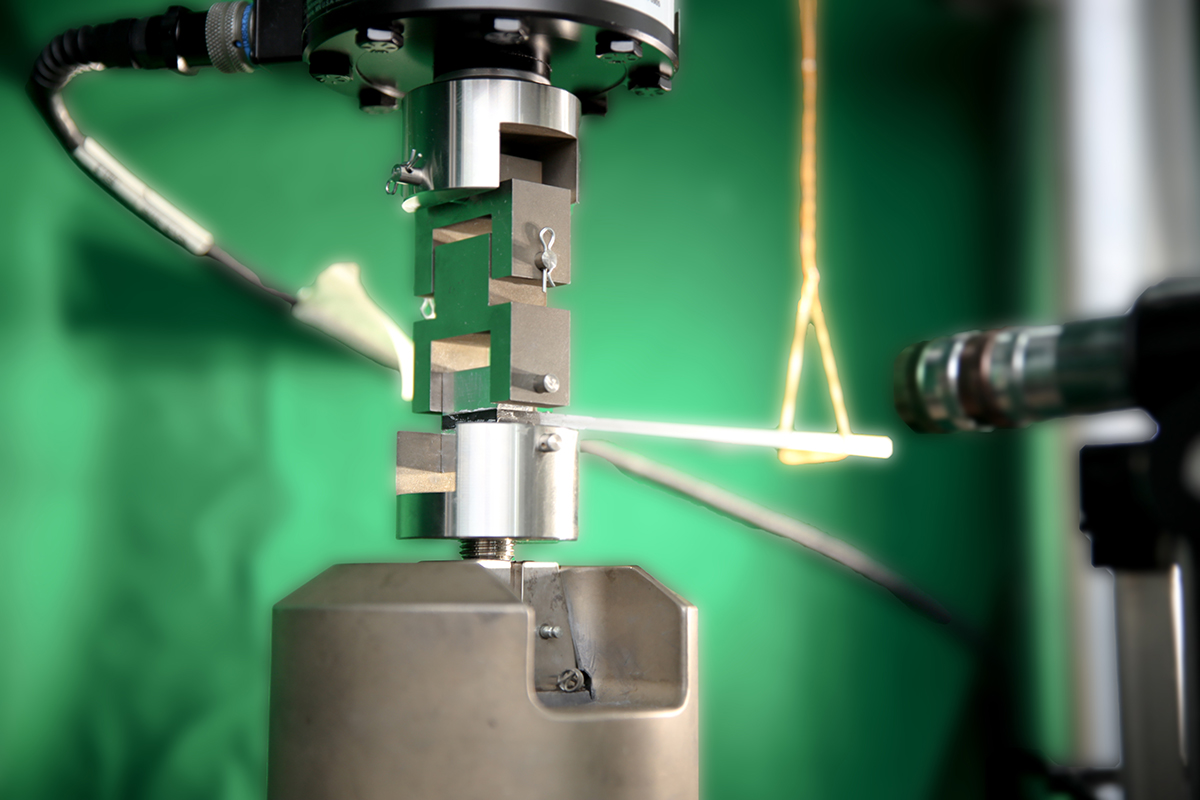

Tensile Testing

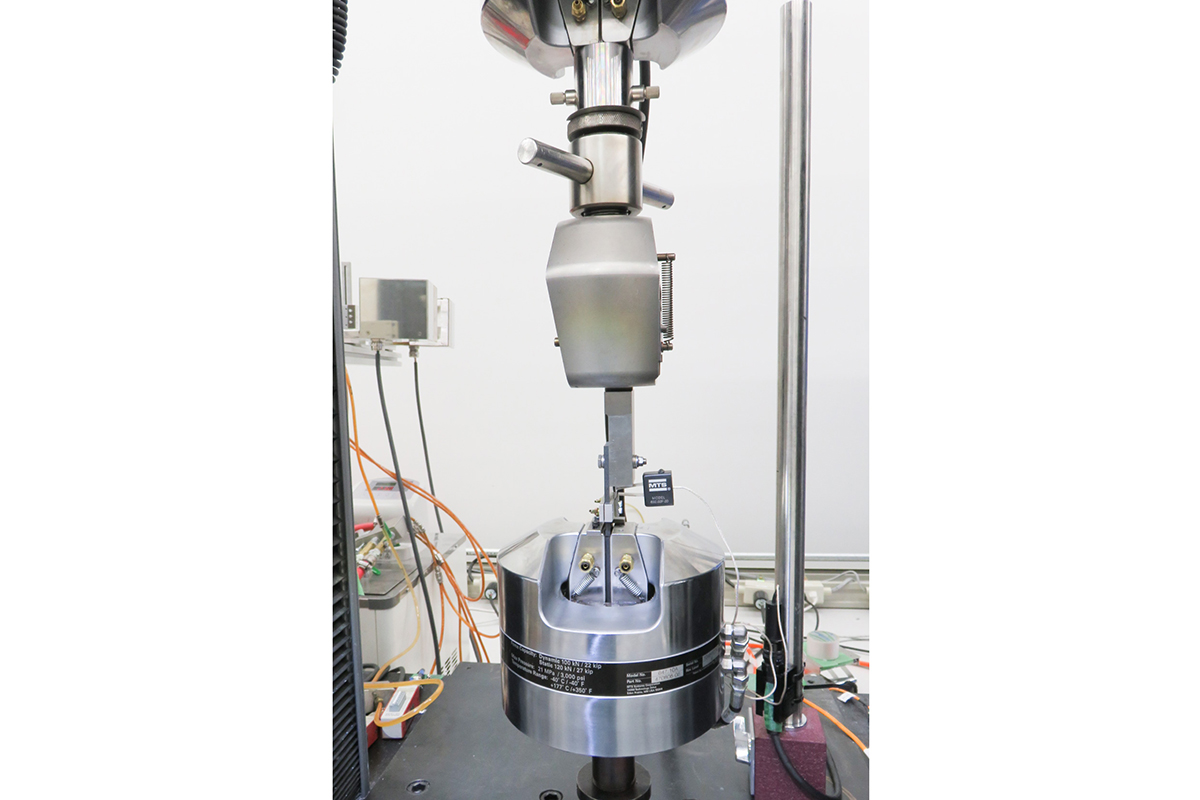

Tensile Testing

Kiguchi is able to perform tensile testing from -130℃ to 315℃ by clamping a test specimen with a high rigidity of the MTS All Temperature Grip.

VIEW

Test Temperature:-150℃ to 300℃

Test Environment:Dry and Wet

Test Force:1kN-500kN

(Test Method/Specification)

-ASTM-

- ASTM C297 Flatwise Tensile Strength of Sandwich Composites

- ASTM D638 Tensile Properties of Plastics

- ASTM D1708 Tensile Properties of Plastics by Use of Microtensile Specimens

- ASTM D3039 Tensile Properties of Polymer Matrix Composite Materials

- ASTM D5766 Open-Hole Tensile Strength of Polymer Matrix Composite Laminates

- ASTM D7291 Through-Thickness “Flatwise” Tensile Strength and Modulus of Composite Materials

-SACMA-

- SACMA SRM 4-88 Tensile Properties of Advanced Composite Materials

- SACMA SRM 5-88 Open-Hole Tensile Properties of Composite Materials

- SACMA SRM 9-88 Bearing Strength of Composite Materials

-JIS-

- JIS K7164 Plastics -- Determination of tensile properties -- Part 4: Test conditions for isotropic and orthotropic fibre-reinforced plastic composites

- JIS K7165 Plastics -- Determination of tensile properties -- Part 5: Test conditions for unidirectional fibre-reinforced plastic composites

- JIS K7094 Test method for open-hole tensile strength of carbon fibre reinforced plastic

ーISO・EN-

- ISO 527-4 Plastics — Determination of tensile properties —

- Part 4: Test conditions for isotropic and orthotropic fibre-reinforced plastic composites

Compression Testing

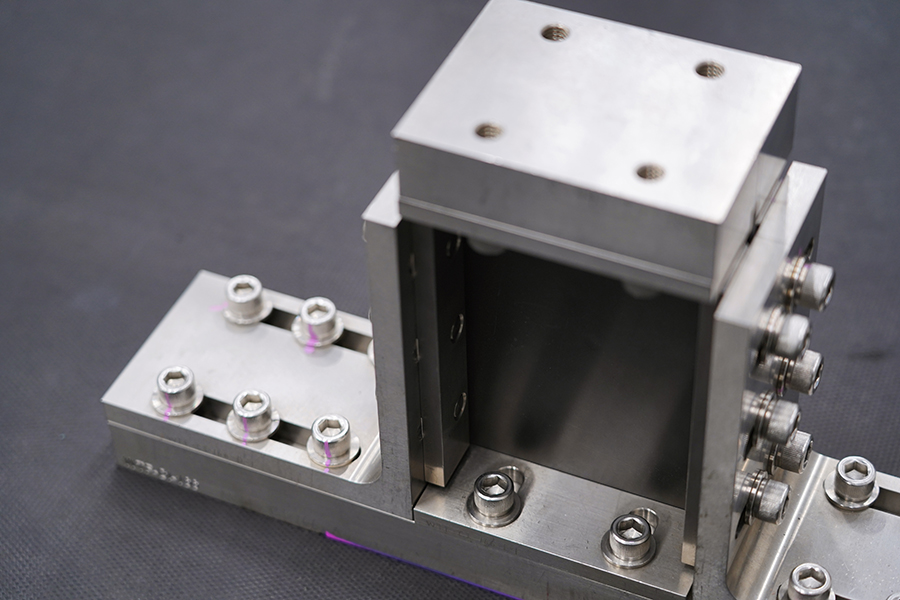

Compression Testing

Kiguchi offers quick testing for customers since we have many compression test fixtures in accordance with ASTM, SACMA, AITM, JIS, ISO, etc.

VIEW

Test Temperature:-150℃ to 300℃

Test Force:1kN-500kN

(Test Method/Specification)

-ASTM-

- ASTM C365 Flatwise Compressive Properties of Sandwich Cores

- ASTM D695 Compressive Properties of Plastics

- ASTM D3410 Compressive Properties of Polymer Matrix Composite Materials

- ASTM D6484 Open-Hole Copmressive Strength of Polymer Matrix Composite Laminates

- ASTM D6641 Compressive Properties of Polymer Matrix Composite Materials Using a Combined Loading Compression (CLC) Test Fixture

- ASTM D7137 Compressive Residual Strength Properties of Damaged Polymer Matrix Composite Plates

-SACMA-

- SACMA SRM 1-88 Compressive Properties of Advanced Composite Materials

- SACMA SRM 2-88 Compressive After Impact

- SACMA SRM 3-88 Open Hole Compression Properties

-JIS-

- JIS K7018 Fiber-reinforced plastic composites -- Determination of compressive properties in the in-plane direction

ーISO・EN-

- ISO 14126 Fibre-reinforced plastic composites – Determination of compressive properties in the in-plane direction

- pr EN285 Aerospace series Carbon fibre thermosetting resin unidirectional laminates Compression test parallel to fibre direction

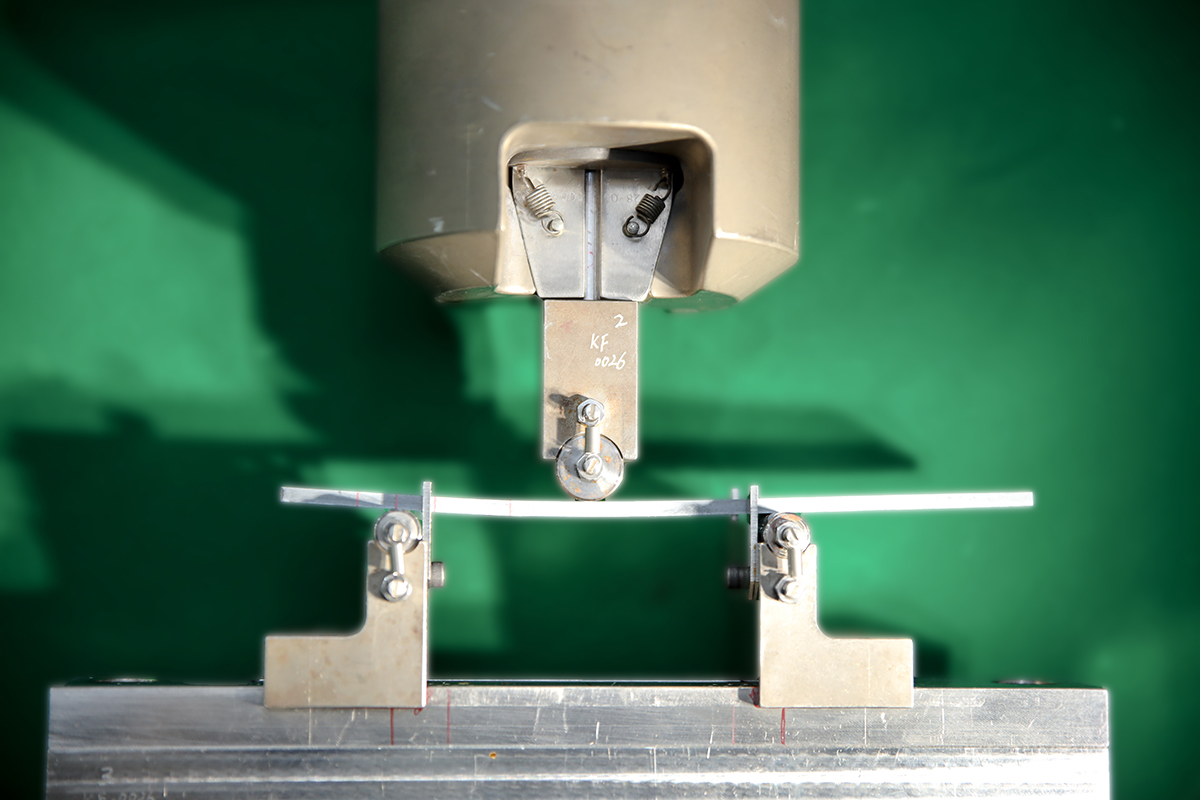

Bend Testing

Bend Testing

Kiguchi is able to perform bend testing with various sizes of test specimens such as a large specimen with support span of over one meter.

VIEW

Test Temperature:-150℃ to 200℃

Test Force:5kN-100kN

(Test Method/Specification)

-ASTM-

- ASTM D790 Flexural Properties of Plastics

- ASTM D6272 Flexural Properties of Plastics by Four-Point Bending

- ASTM D7264 Flexural Properties of Composites by Four-Point Bending

- ASTM D7249 Standard Test Method for Facesheet Properties of Sandwich Constructions by Long Beam Flexure

-JIS-

- JIS K7074 Testing methods for flexural properties of carbon fiber reinforced plastics

- JIS K7084 Testing method for impact properties of carbon fibre reinforced plastics by instrumented 3-point bending impact test

ーISO・EN-

- ISO 14125 Fibre-reinforced plastic composites — Determination of flexural properties

Shear Testing

Shear Testing

One of the properties of CFRP is that its brittle: it easily conduct interlaminar shear failure by external impacts depending on the resin base, since it has no reinforcing fibers in the through-thickness direction.

Therefore, there are many shear property tests. Kiguchi is able to perform almost all shear testing specified in official standards.

VIEW

Test Temperature:-150℃ to 300℃

Test Force:1kN-500kN

(Test Method/Specification)

-ASTM-

- ASTM D1002 Single Lap Shear of Adhesive Bonded Joints

- ASTM D2344 Short-Beam Strength of Polymer Matrix Composite Materials

- ASTM D3518 In-Plane Shear Response of Polymer Matrix Composite Materials by Tensile Test of a ±45° Laminate

- ASTM D3846 Double Notch Shear (Interlaminar)

- ASTM D5379 Shear Properties of Composite Materials by the V-Notched Beam Method

- ASTM D5961 Bearing Response of Polymer Matrix Composite Laminates (Procedure A~D)

- ASTM D7078 Shear Properties of Composite Materials by the V-Notched Rail Shear Method

-SACMA-

- SACMA SRM 7-88 Inplane Shear Stress-Strain Properties (±45°)

- SACMA SRM 8-88 Apparent Interlaminar Shear Strength by the Short-Beam Method

-JIS-

- JIS K7057 Fibre-reinforced plastic composites -- Determination of apparent interlaminar shear strength by short-beam method

- JIS K7019 Fiber-reinforced plastic composites -- Determination of the in-plane shear stress/shear strain response, including the in-plane shear modulus and strength, by the plus and minus 45 degree SIGN tension test method

ーISO・EN-

- ISO 14130 Fibre-reinforced plastic composites — Determination of apparent interlaminar shear strength by short-beam method

Bearing Testing

Bearing Testing

Kiguchi is able to perform all four bearing test methods specified in ASTM D5971. Also, we can obtain fasteners per international standards.

VIEW

Test Temperature:-150℃ to 300℃

Test Force:1kN-500kN

(Test Method/Specification)

- ASTM D5961 Standard Test Method for Bearing Response of Polymer Matrix Composite Laminates

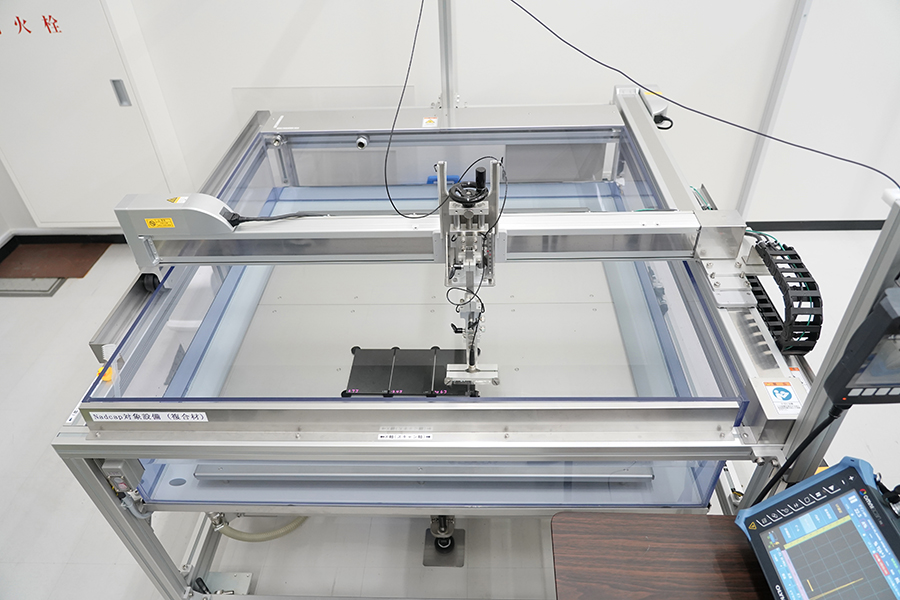

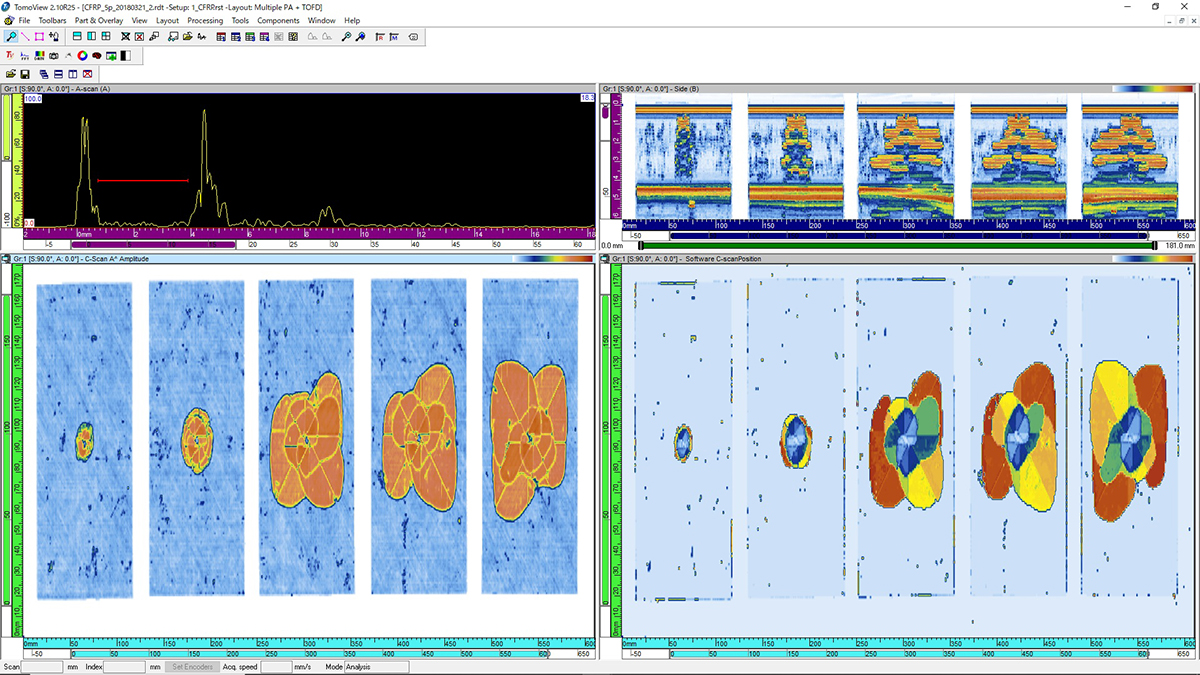

CAI (Compression After Impact) Testing

CAI (Compression After Impact) Testing

CFRP laminated plates have high strength in fiber direction. However, they are prone to damage such as matrix cracking and delamination due to the low strength perpendicular to the fibers and interlaminar. As a result, static strength decrease and fatigue life deterioration will occur. Therefore, CAI tests are required for evaluating the performance of CFRP, since the compressive strength of composite laminated plates under impact loading is significantly decreased.

VIEW

(Test Flow)

Provide an impact on a specimen

↓

Internal Damage Evaluation by Ultrasonic Test

↓

Define the Remaining Strength (Compression Testing)

(Test Method/Specification)

- ASTM D7136 Standard Test Method for Measuring the Damage Resistance of a Fiber-Reinforced Polymer Matrix Composite to a Drop-Weight Impact Event

- ASTM D71367 Standard Test Method for Compressive Residual Strength Properties of Damaged Polymer Matrix Composite Plates

- ISO6603-2 Plastics — Determination of puncture impact behaviour of rigid plastics — Part 2: Instrumented impact testing

(Temparature Range)

- Provide an impact on a specimen in the range of -70℃ to 150℃

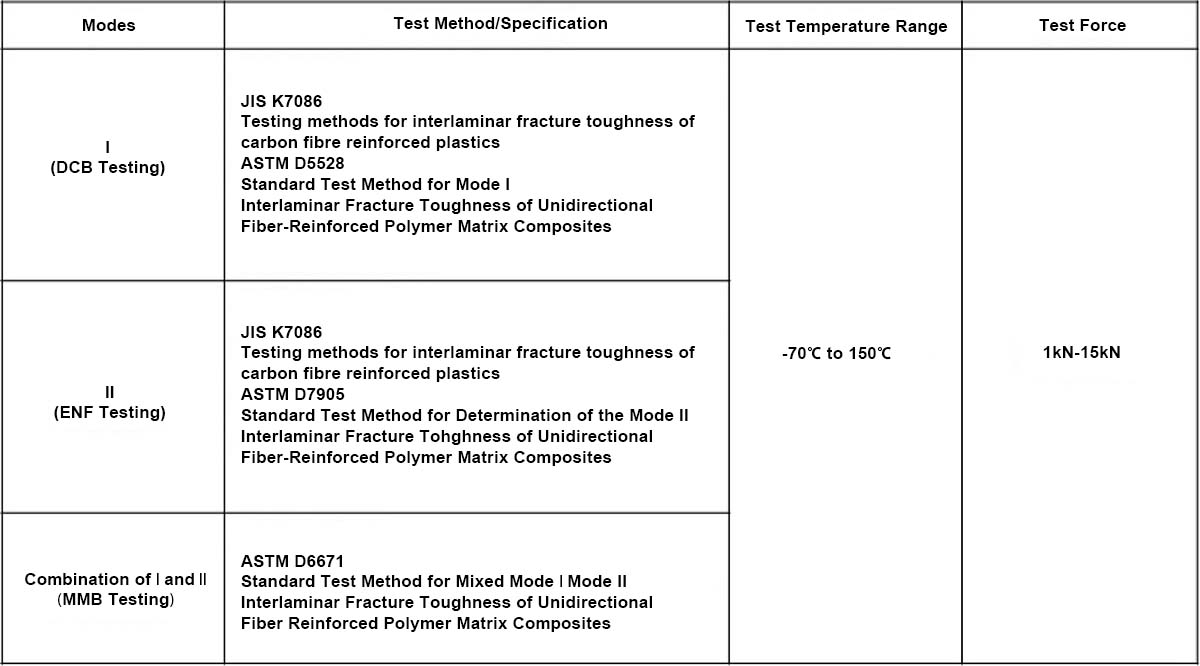

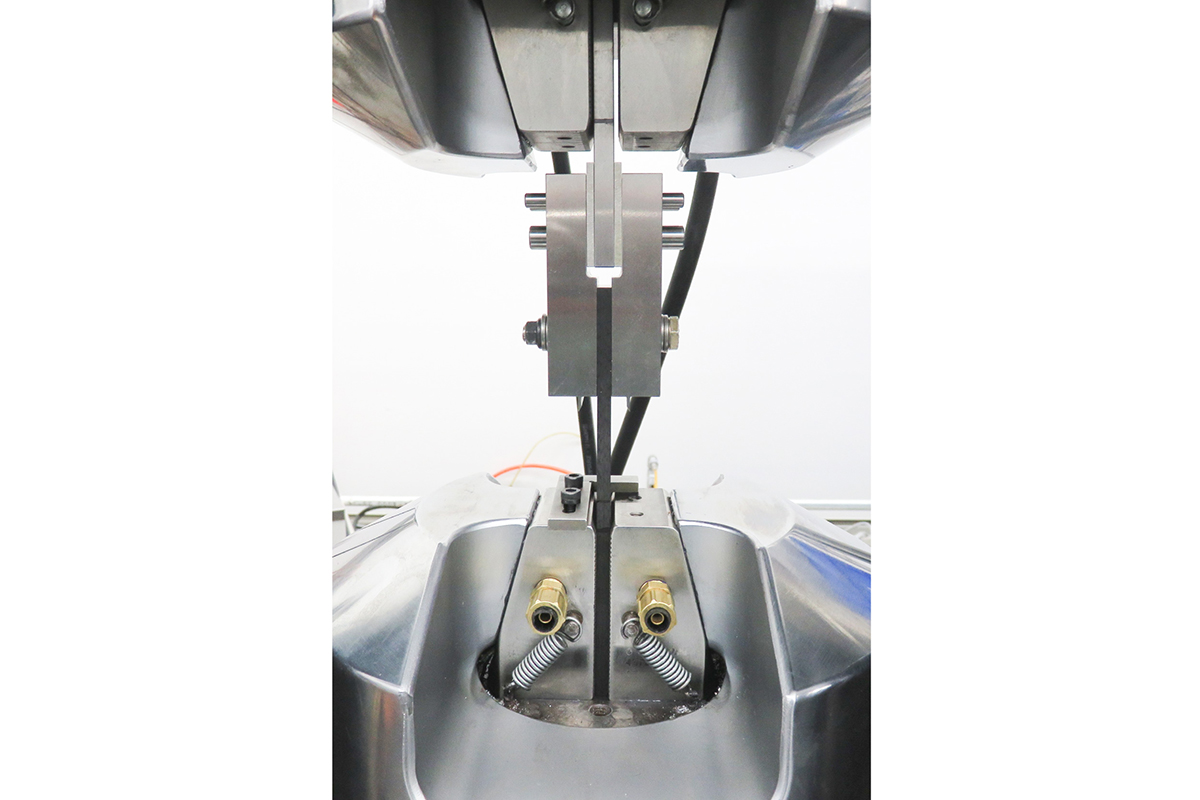

Interlaminar Fracture Toughness Testing

Interlaminar Fracture Toughness Testing

CFRP has low interlaminar strength since it has no reinforcing fibers in the through-thickness direction. Therefore, not only the strength evaluation of CFRP but also the evaluation of delamination and crack growth are required for designing with CFRP. There are three types of fracture modes: Mode I – Opening, ModeⅡ– Sliding, and ModeⅢ– Tearing. Kiguchi offers the tests in Mode I, ModeⅡ, and the combination of Mode I and ModeⅡ.

VIEW