SERVICE

MATERIALS TESTING (METALS)

Mechanical Testing

Continuously innovating and evolving.

High-Reliability of Services

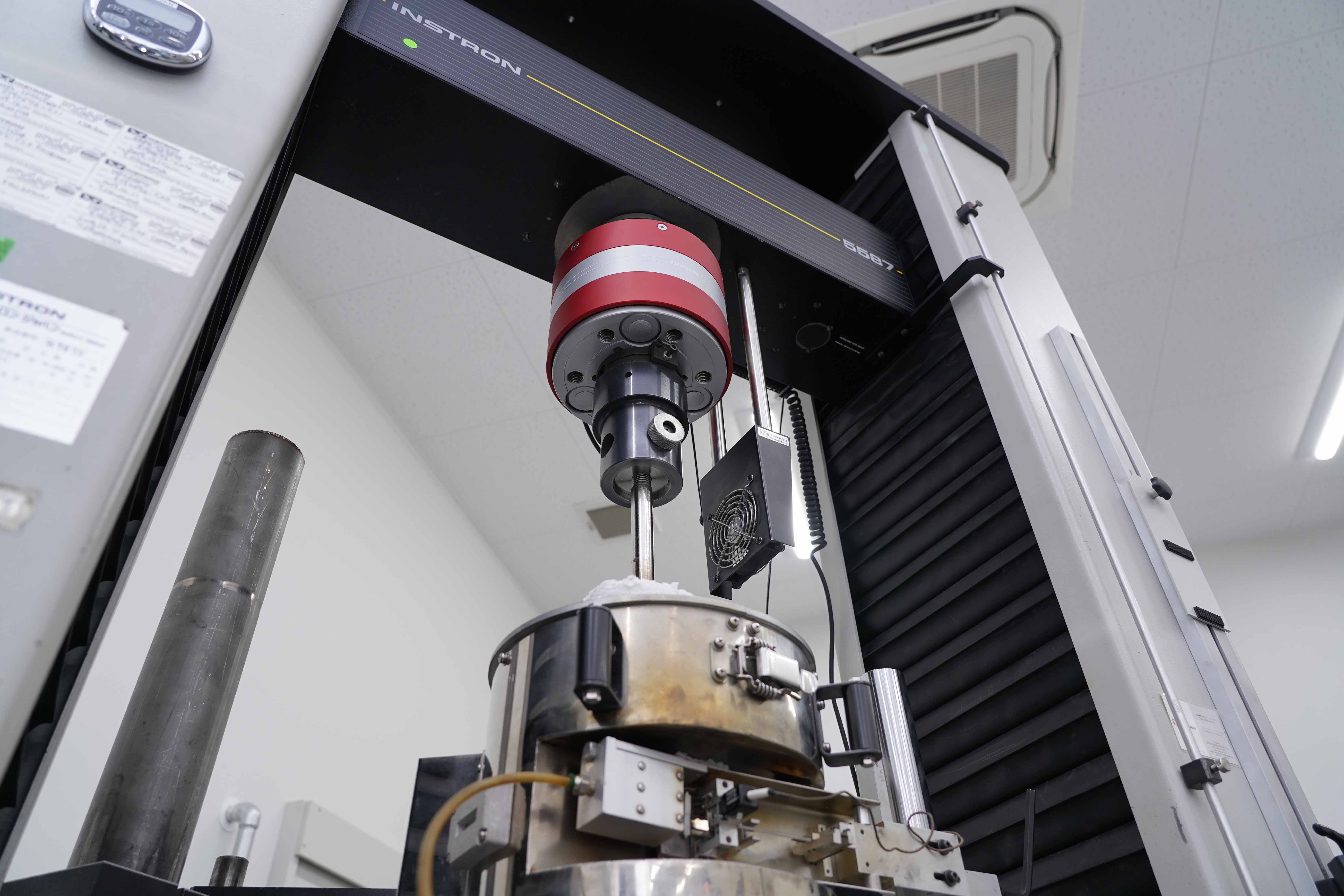

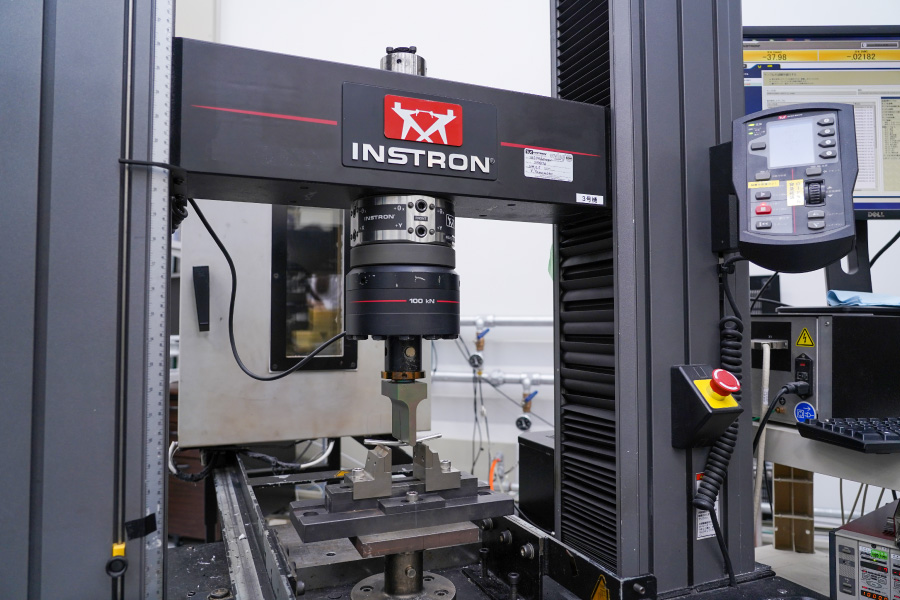

Kiguchi is flexible in performing various types of tests from tests in accordance with official standards to tests tailored to customer requirements. We are equipped with 20 test machines, mainly manufactured by Instron, and we perform approximately 100,000 tests per year.

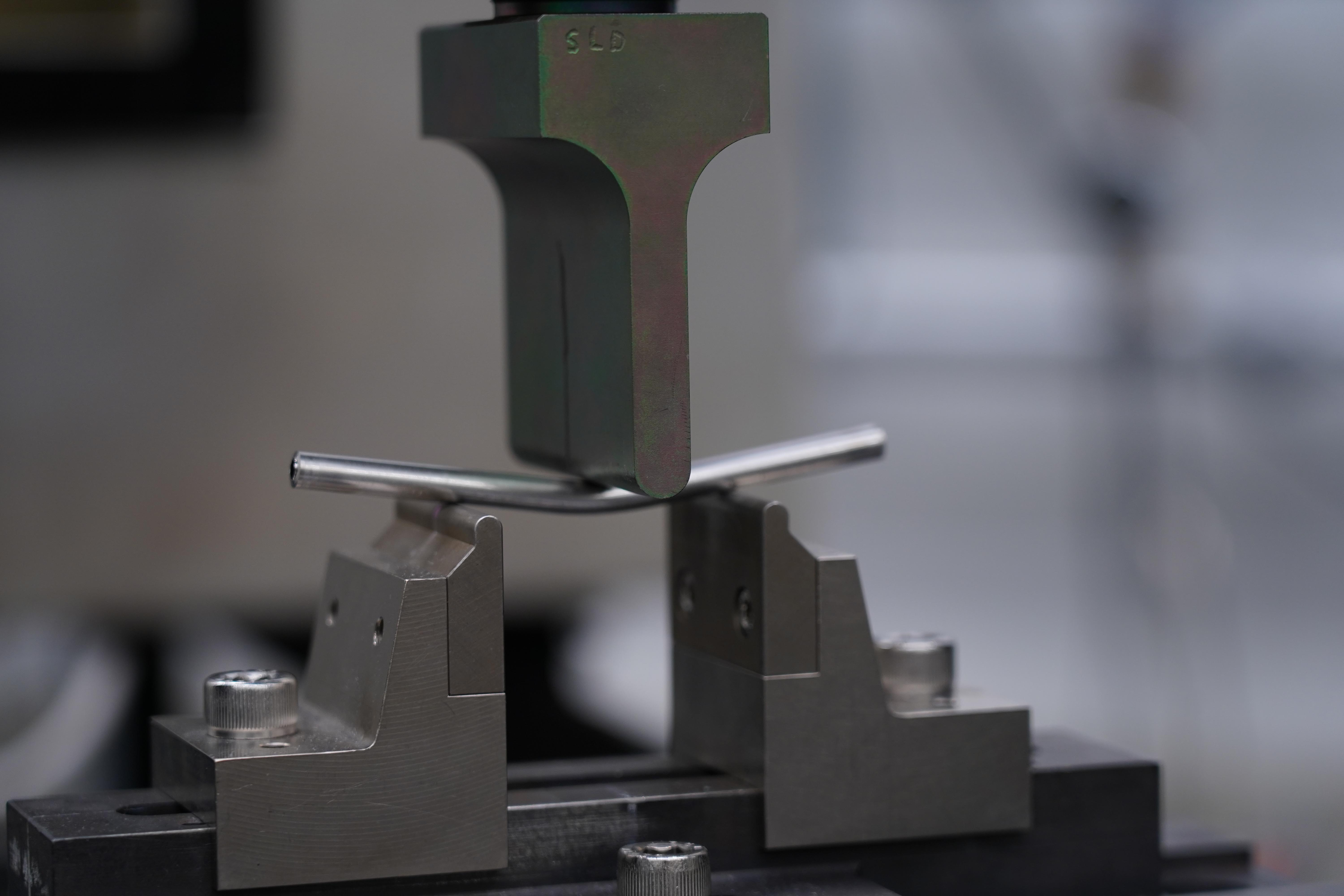

Tensile Testing

Tensile Testing

【Main Test Material】

Steel, cast iron, aluminum alloy, titanium alloy, copper alloy, heat-resistant alloy, and three-dimensional laminated material

【Temperature Range】-196℃ to 1200℃

【Test Force】 100N - 500kN

【Main Test Specimen Shape】

Cylindrical, flat, film, wire, and pipe

【Date Acquired】

0.2% yield strength, tensile strength, elongation, reduction of area, young modulus, Poisson’s ratio, n value, and r value

See details

【Test Method/Specification for Metallic Materials】

- ASTM E8/E8M: Standard Test Methods for Tension Testing of Metallic Materials

- ISO 6892-1: Metallic materials - Tensile testing – Part 1:Method of test at ambient temperature

- ISO 6892-2: Metallic materials - Tensile testing – Part 2:Method of test at elevated temperature

- JIS Z2241 Metallic materials -- Tensile testing -- Method of test at room temperature

- JIS Z3040 Method of qualification test for welding procedure

- JIS Z3111 Methods of tension and impact tests for deposited metal

- JIS Z3121 Methods of tensile test for butt welded joints

【Test Method/Specification for Fasteners and Rivets】

- ASTM F606 / F606M Standard Test Methods for Determining the Mechanical Properties of Externally and Internally Threaded Fasteners, Washers, Direct Tension Indicators, and Rivets

- NASM 1312-8 Fastener Test Methods - Method 8 - Tensile Strength

- ISO 14589 Blind rivets — Mechanical testing

- ISO 13469Mechanical joining — Form-fit blind rivets and (lock) bolt joints — Specifications and qualification of testing procedures

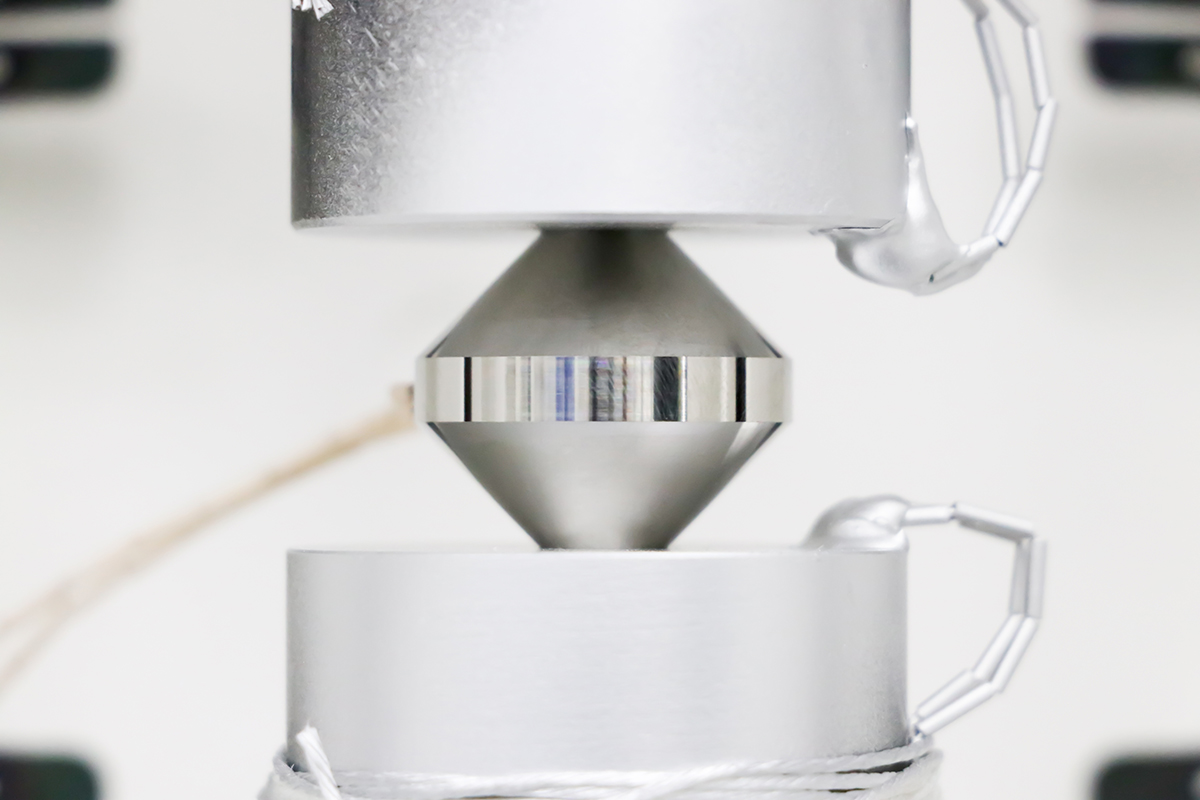

Compression Testing

Compression Testing

【Main Test Material】

Steel, cast iron, aluminum alloy, titanium alloy, copper alloy, heat-resistant alloy, three-dimensional laminated material, etc.

【Temperature Range】-196℃ to 1200℃

【Test Force】 100N - 500kN

【Main Test Specimen Shape】

Cylindrical, pipe, and flat

【Date Acquired】

x% compressive strength, compressive strength, and Poisson’s ratio

See details

【Test Method/Specification for Metallic Materials】

- ASTM E9 Standard Test Methods of Compression Testing of Metallic Materials at Room Temperature

- ASTM E209 Standard Practice for Compression Tests of Metallic Materials at Elevated Temperatures with Conventional or Rapid Heating Rates and Strain Rates

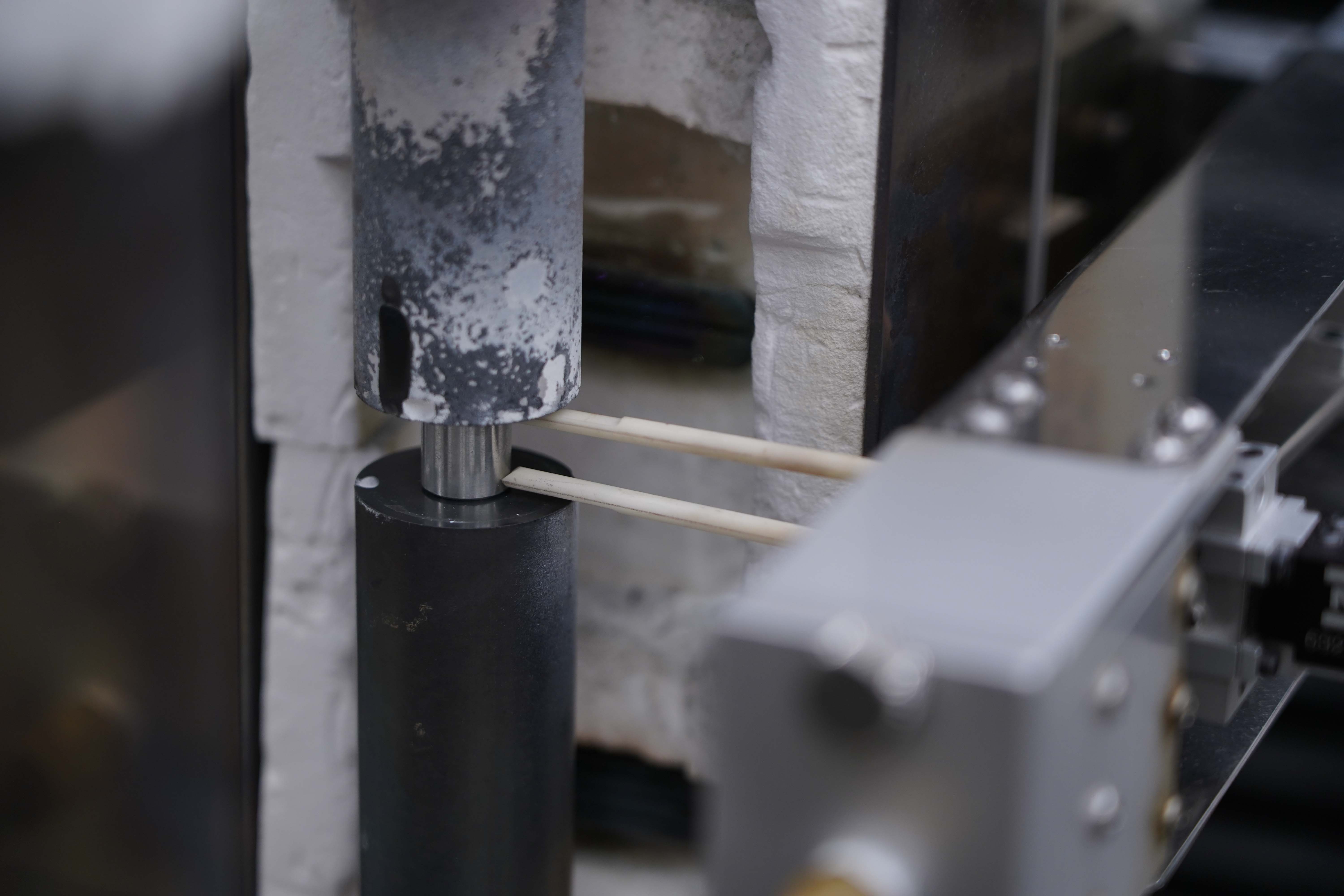

Bend Testing

Bend Testing

【Main Test Material】

Steel, cast iron, aluminum alloy, titanium alloy, copper alloy, heat-resistant alloy, three-dimensional laminated material, etc.

【Test Method】

Three point bending and four point bending

【Temperature Range】-196℃ to 900℃

【Test Force】 100N - 500kN

【Main Test Specimen Shape】

Cylindrical, flat, and pipe

【Date Acquired】

Bending strength, bending strain, and existence of cracks on the bended surface

See details

【Test Method/Specification】

- ASTM A370 Standard Test Methods and Definitions for Mechanical Testing of Steel Products

- ASTM E290 Standard Test Methods for Bend Testing of Material for Ductility

- BS EN 910 Destructive tests on welds in metallic materials. Bend tests

- JIS Z 3122 Methods of bend test for butt welded joint

- ISO 5173 Destructive tests on welds in metallic materials — Bend tests

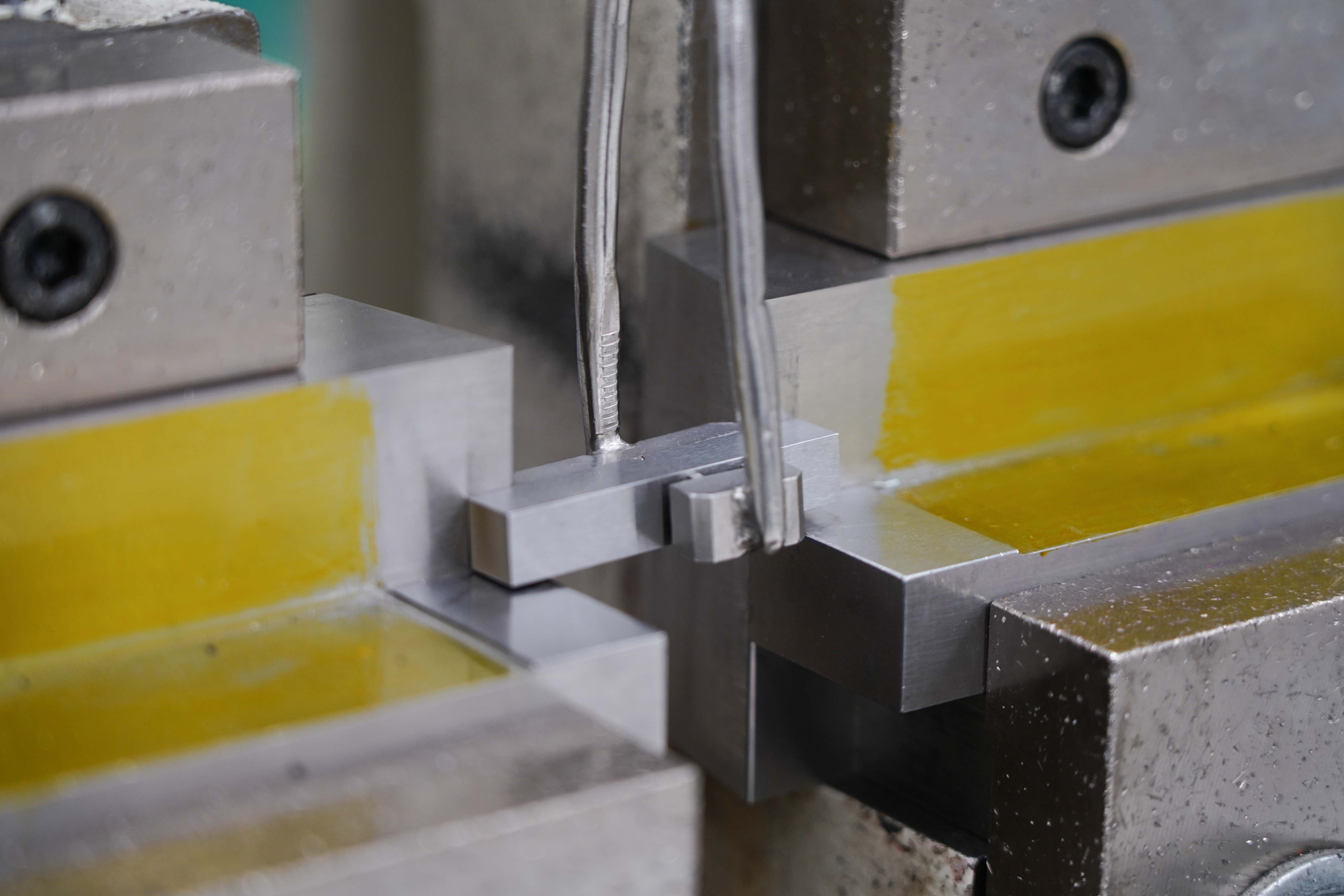

Shear Testing

Shear Testing

【Main Test Material】

Steel, cast iron, aluminum alloy, titanium alloy, copper alloy, heat-resistant alloy, three-dimensional laminated material, etc.

【Test Method】

Three point bending and four point bending

【Temperature Range】-196℃ to 900℃

【Test Force】 100N - 500kN

【Main Test Specimen Shape】

Cylindrical, flat, and pipe

【Date Acquired】

Shear strength

See details

【Test Method/Specification for Metallic Materials】

- ASTM B769 Standard Test Method for Shear Testing of Aluminum Alloys

【Test Method/Specification for Fasteners and Rivets】

- NASM 1312-13 Fastener Test Methods Method 13 Double Shear Test

Impact Testing

Impact Testing

【Temperature Range】-196℃ to 1000℃

【Test Machine Load Capacity】

JIS Z2242:300J/500J, ASTM E23:360J

【Test Specimen Type】

Standard size, sub-size, U-notch, V-notch, keyhole, and a specimen without notch

【Date Acquired】

Absorbed energy, lateral expansion, percent brittle area, and FATT (Fracture appearance transition temperature)

See details

【Test Method/Specification】

- JIS Z2242 Method for Charpy pendulum impact test of metallic materials

- ASTM E23 Standard Test Methods for Notched Bar Impact Testing of Metallic Materials

Creep Testing

Creep Testing

【Temperature Range】200℃ to 1000℃

【Test Force】 15kN, 30kN, and 300kN

【Loading Type】

Tensile, compressive and bending creep

【Date Acquired】

Time for rupture, elongation, reduction of area, minimum creep rate, and time to x% creep

See details

【Test Method/Specification for Metallic Materials】

- JIS Z2271 Metallic materials -- Uniaxial creep testing in tension -- Method of test

- ASTM E139 Standard Test Methods for Conducting Creep, Creep-Rupture, and Stress-Rupture Tests of Metallic Materials

- ASTM E292 Standard Test Methods for Conducting Time-for-Rupture Notch Tension Tests of Materials

- ASTM F519 Standard Test Method for Mechanical Hydrogen Embrittlement Evaluation of Plating/Coating Processes and Service Environments

- NASM 1312-10 Fastener Test Methods Method 10 Stress Rupture

Creep Crack Growth Testing

【Test Method/Specification for Metallic Materials】

- JSMS-SD-12-16 Standard Test Method for High Temperature Creep and Creep Fatigue Crack Growth Tests

- ASTM E1457 Standard Test Method for Measurement of Creep Crack Growth Times in Metals

【Temperature Range】200℃ to 1000℃

【Test Force】30kN

【Test Specimen Type】 CT, CS(T), M(T), DEN(T), SEN(T), and SEN(B)

【Date Acquired】 da/dtー⊿K, da/dtーC*, and aーtime

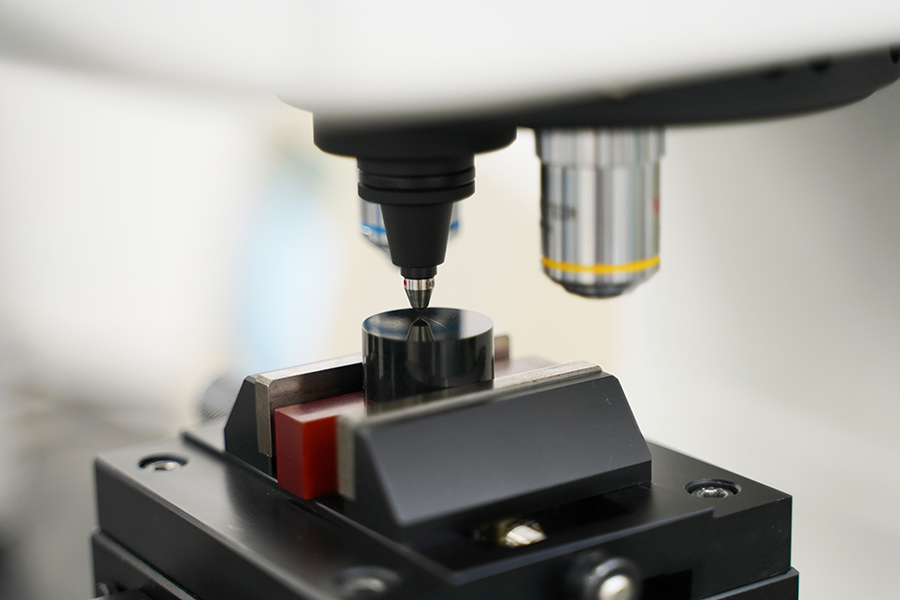

Hardness Testing

Hardness Testing

【Main Test Material】

Steel, cast iron, aluminum alloy, titanium alloy, copper alloy, heat-resistant alloy, three-dimensional laminated material, etc.

【Temperature Range】

Ambient temperature only

【Test Type】

Vickers hardness, Rockwell hardness, and Brinell hardness

【Test Condition】

Vickers hardness:0.1 - 30kgf, Rockwell hardness:Scales B and C, Brinell hardness:10mm/3000kgf, 5mm/750kgf

See details

【Test Method/Specification】

- ASTM E92 Standard Test Methods for Vickers Hardness and Knoop Hardness of Metallic Materials

- ASTM E18 Standard Test Methods for Rockwell Hardness of Metallic Materials

- ASTM E10 Standard Test Method for Brinell Hardness of Metallic Materials

- JIS Z2244 Vickers hardness test -- Test method

- JIS Z2245 Rockwell hardness test -- Test method

- JIS Z2243-1 Brinell hardness test – Part 1:Test method