SERVICE

MATERIALS TESTING (METALS)

Fatigue Testing

Continuously innovating and evolving.

In order to be of a high global standard

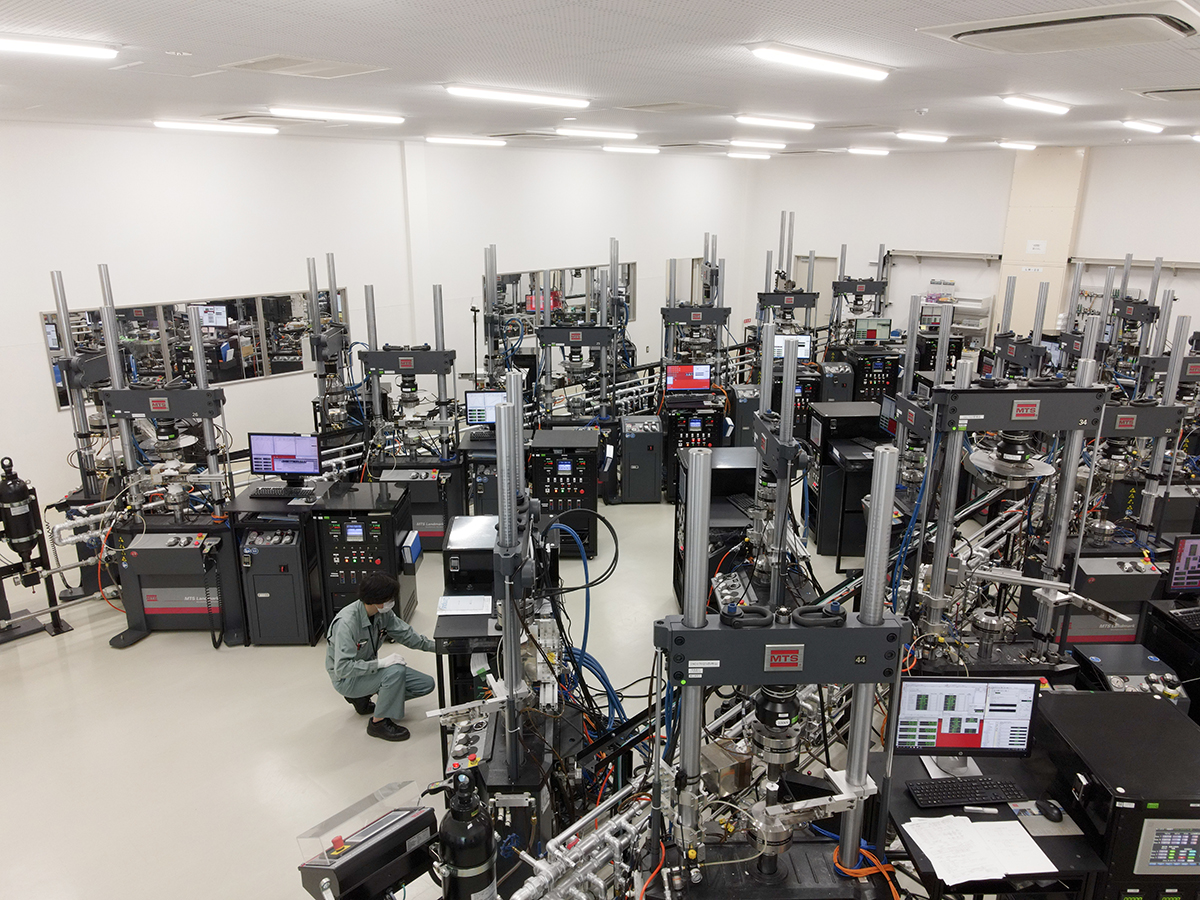

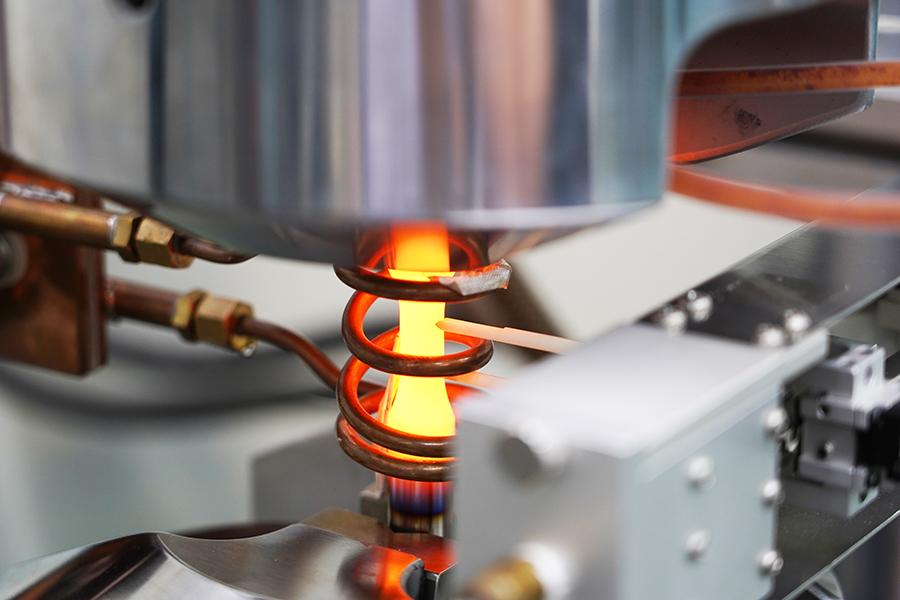

Kiguchi evaluates fatigue properties testing with a large quantity of test machines under various conditions. For high temperature testing, we offer a variety of testing from mass product specification testing, to the original testing using suitable electric furnaces and induction heating devices according to the material properties.

Rotating Bending Fatigue Testing

Rotating Bending Fatigue Testing

Rotating Bending Fatigue Testing is performed by rotating a cylindrical specimen to which a bending moment is applied. Kiguchi uses the Ono-type rotating bending fatigue test machine, and the tests are performed by applying sine waves in reversed loadings(σm=0、R=-1).

See details

The test offers inexpensive means to collect basic data about fatigue strength design. The result of the tests is provided as the S-N Curve.

【Test Method/Specification】

- JIS Z2274 Method of Rotating Bending Fatigue Testing of Metals

- ISO 1143 Metallic materials — Rotating bar bending fatigue testing

【Temperature Range】RT~850℃

【Environment】

Ambient (Further discussion is needed for varying conditions.)

【Test Specimen Size】

Gage section diameter-Grip section diameter-Total length:8-12-90mm(Room temp, Elevated temp): 10-12-210mm (Room temp)

【Data Acquired】

Number of cycles to failure

High Cycle Fatigue Testing

High Cycle Fatigue Testing

High Cycle Fatigue Testing evaluates materials within their elastic range. Normally, the tests are performed in load/force control, and the number of cycles to failure are 105 cycles or more.

See details

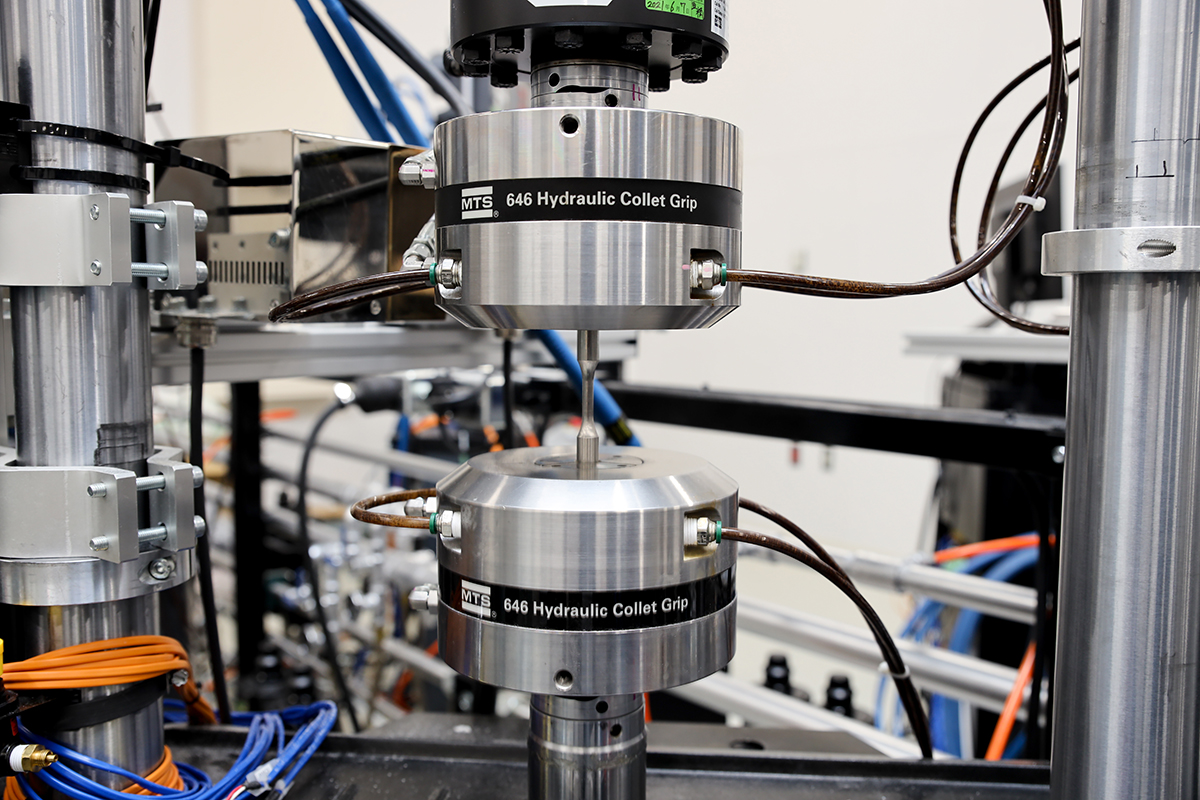

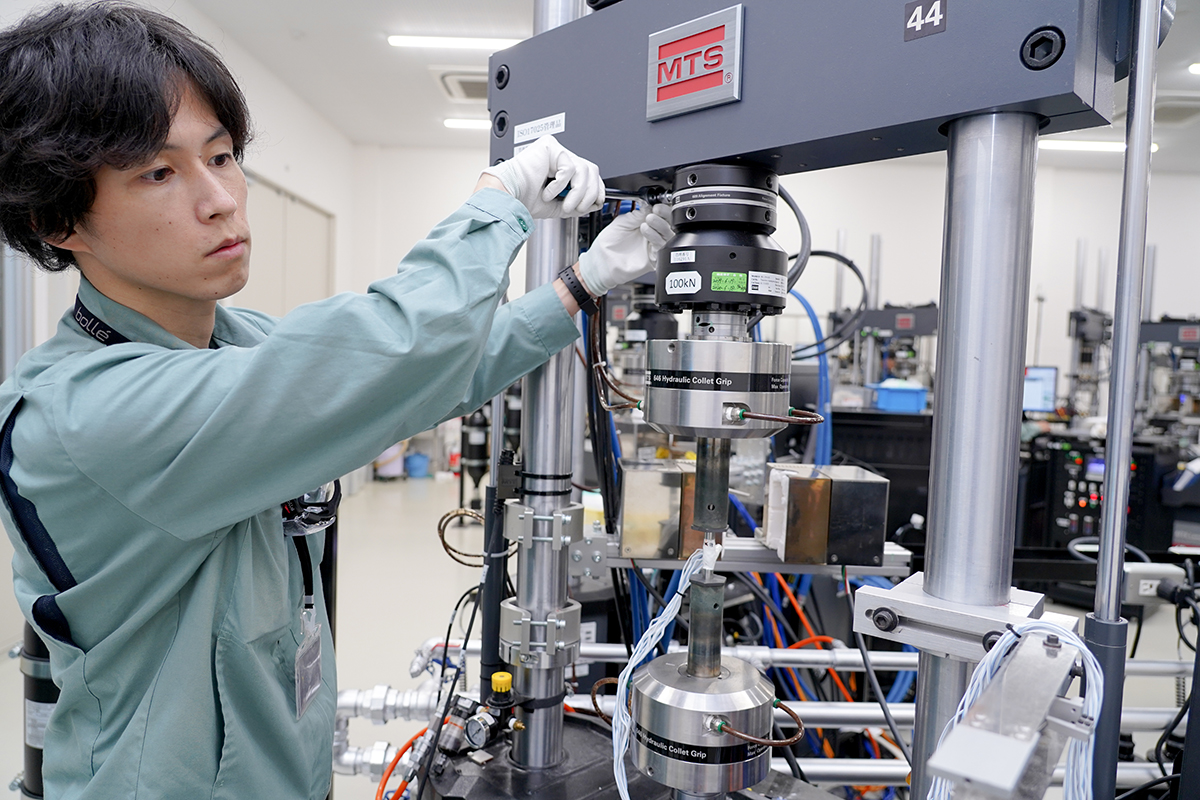

Longitudinal polished specimen with a smooth gage section (i.e., cylindrical specimen and flat specimen) is installed to a test machine and tested in load/force control at 5Hz-100Hz. Kiguchi has the MTS servohydraulic load frames and the state-of-the-art hydraulic system to minimize crosstalk and hydraulic pulsation.

【Test Method/Specification】

- ASTM E466 Standard Practice for Conducting Force Controlled Constant Amplitude Axial Fatigue Tests of Metallic Materials

- E50TF587 AXIAL LOAD CONTROL HIGH CYCLE FATIGUE TESTING OF METALLIC SPECIMENS

【Temperature Range】-196℃ to 1100℃

【Test Force】3kN-500kN

【Heating Method】

Electric furnace, induction heating, and direct electric heating.

【Control Mode】

Stress and load

【Frequency】

Up to 150Hz

【Test Specimen】

Gage section diameter 1-10mm, total length 30-150mm, grip section:Threaded, button head, and straight

【Data Acquired】

Number of cycles to failure

Low Cycle Fatigue Testing

Low Cycle Fatigue Testing

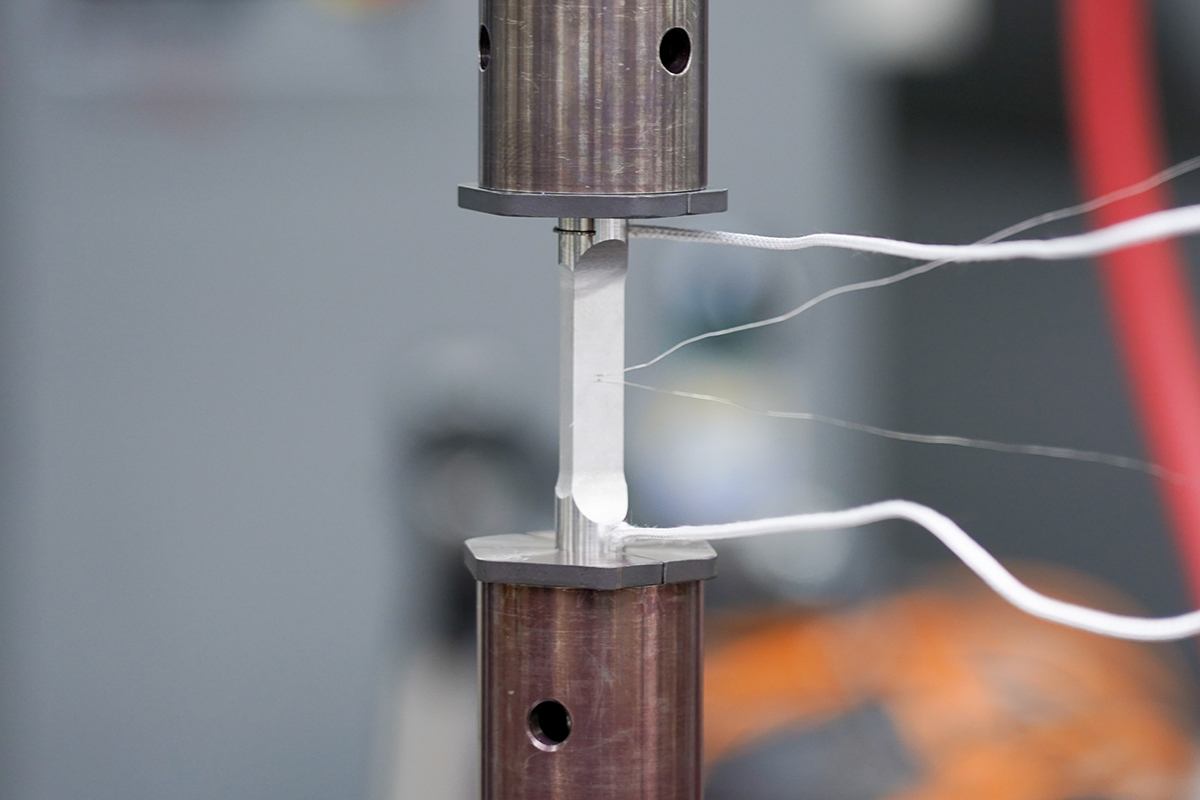

Low cycle fatigue testing involves applying a load that causes plastic deformation to the specimen. The number of cycles to failure are less than 104 cycles. Kiguchi offers various fields tests including ASTM E606.

See details

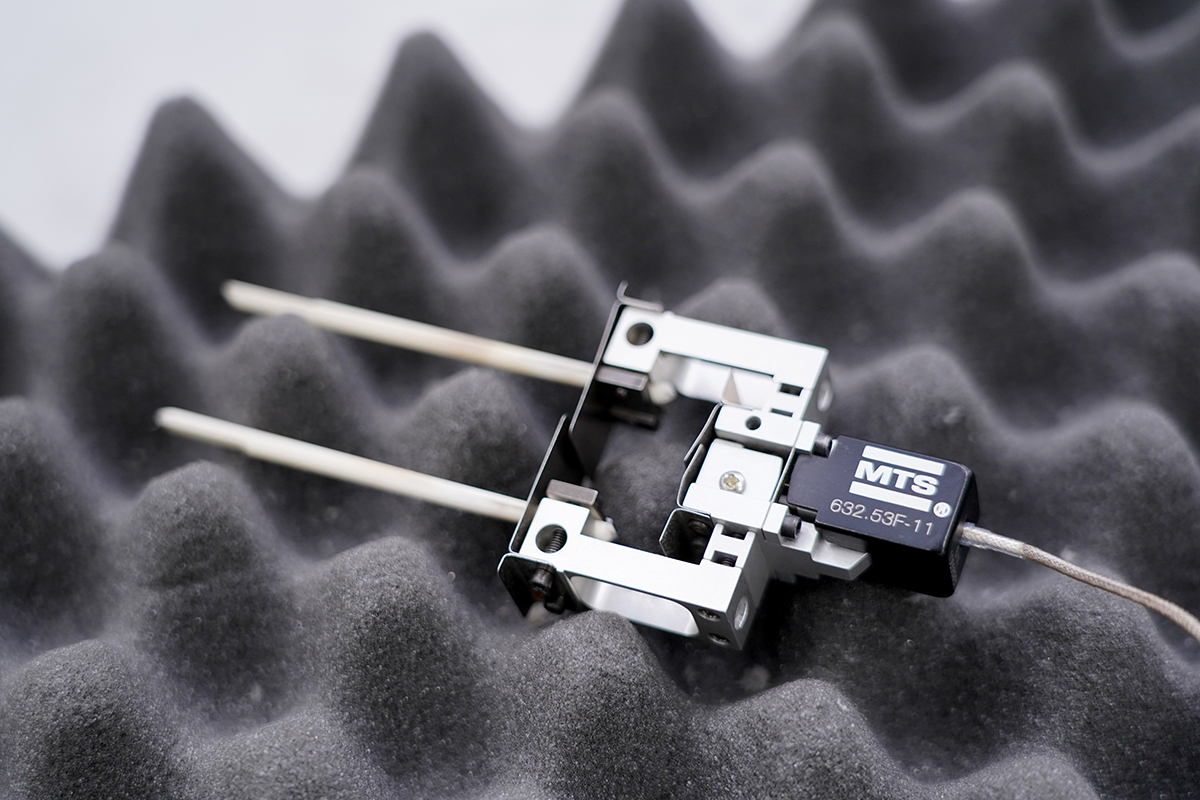

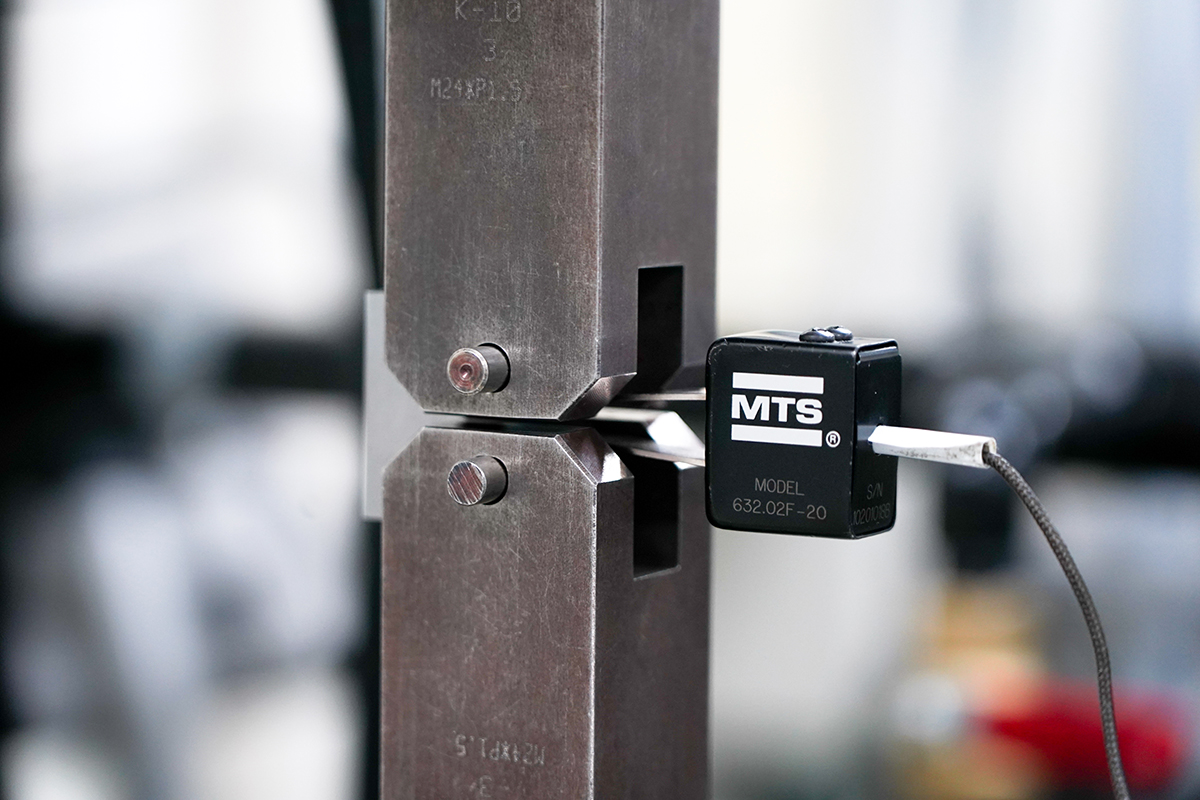

Longitudinal polished specimens with a smooth gage section (i.e., cylindrical specimen and flat specimen) are installed to a test machine and tested in strain control. Kiguchi has the MTS servohydraulic load frames. We provide tests with reliable accuracy since our extensometers are calibrated in Class B-1 or B-2 per ASTM E83 every 6 months.

【Test Method/Specification】

- JIS Z2279 Method of high temperature low cycle fatigue testing for metallic materials

- ASTM E606/E606M Standard Test Method for Strain-Controlled Fatigue Testing

- E50TF148 AXIAL STRAIN CONTROL LOW CYCLE FATIGUE TESTING OF METAL TEST BARS

- DMC0401 Strain-controlled Low-cycle Fatigue Test

【Temperature Range】

RT to 1200℃(Except for certain temperatures)

【Test machine】MTS 370, MTS 810, etc.

【Test Force】3kN-500kN

【Heating Method】

Electric furnace, induction heating etc.

【Control Mode】

Strain control, total strain range, plastic strain, and control of constant-strain holding

【Frequency】Up to 3Hz

【Test Specimen】

Gage section diameter 1-10mm, total length 30-150mm, grip section:Threaded, button head, and straight

【Data Acquired】

Number of cycles to failure, elastic strain, plastic strain, stress transition, and young modulus transition

Thermomechanical Fatigue (TMF) Testing

Thermomechanical Fatigue (TMF) Testing

In general, low cycle fatigue testing and high cycle fatigue testing are performed at elevated temperature. TMF testing evaluates material properties when cyclic thermal fluctuations and mechanical strain occur simultaneously. The test evaluates the material properties and behaviors of steam turbines for thermal power generation, jet engines for airplanes, automotive parts, etc.

See details

TMF testing is normally performed per ASTM E2368. Kiguchi is flexible for customer requests such as temperature and control modes. Also, we achieve periodic temperature fluctuations basically using a high-frequency heating device.

We offer minimal data difference since our MTS servohydraulic load frames are applied the same heating system as possible.

【Test Method/Specification】

- ASTM E2368 Standard Practice for Strain Controlled Thermomechanical Fatigue Testing

- ISO12111 Metallic materials — Fatigue testing — Strain-controlled thermomechanical fatigue testing method

【Temperature Range】-196℃ to 1200℃

【Temperature Change Rate】5℃/sec

【Test Force】3kN-250kN

【Heating Method】

Induction Heating (10kW, 20kW), direct electric heating, and infrared lamp heater

【Control Mode】

Mechanical strain control and control of constant-strain holding

【Strain Control and Temperature Control】

In-Phase, Out-of-Phase, and Diamond Phase

【Specimen Type】

Solid cylindrical specimen, hollow cylindrical specimen, and panel shape

【Evaluation Parts】

Automotive:cylinder head, exhaust manifold, piston, exhaust valve, and gas turbine is evaluated by DSS (daily start and stop) driving simulation test.

【Data Acquired】

Number of cycles to failure, elastic strain, plastic strain, stress transition, and young modulus transition

Fracture Toughness Testing

Fracture Toughness Testing

Fracture toughness testing determines the fracture mechanical parameters for stable and unstable crack growth initiation. KIC tests are performed under a plane-strain condition, and JIC tests are performed based on elastic-plastic fracture mechanics.

See details

There are many cases where KIC testing is not possible due to a number of reasons. Firstly the limitation of material size, then test machine capacity. Thirdly the test has strict specimen sizes to obtain effective toughness values, and lastly larger specimens are required for high-toughness materials.

Testing Standard:ASTM E399 and ASTM E1820

Environment:Ambient(Further discussion is needed for varying conditions.)

Test Temperature:RT to 900℃(Except for certain temperatures)

Test Machine:MTS370, MTS 810, etc.

Test Force:3-250[kN]

Measurement of Crack Length: compliance method etc.

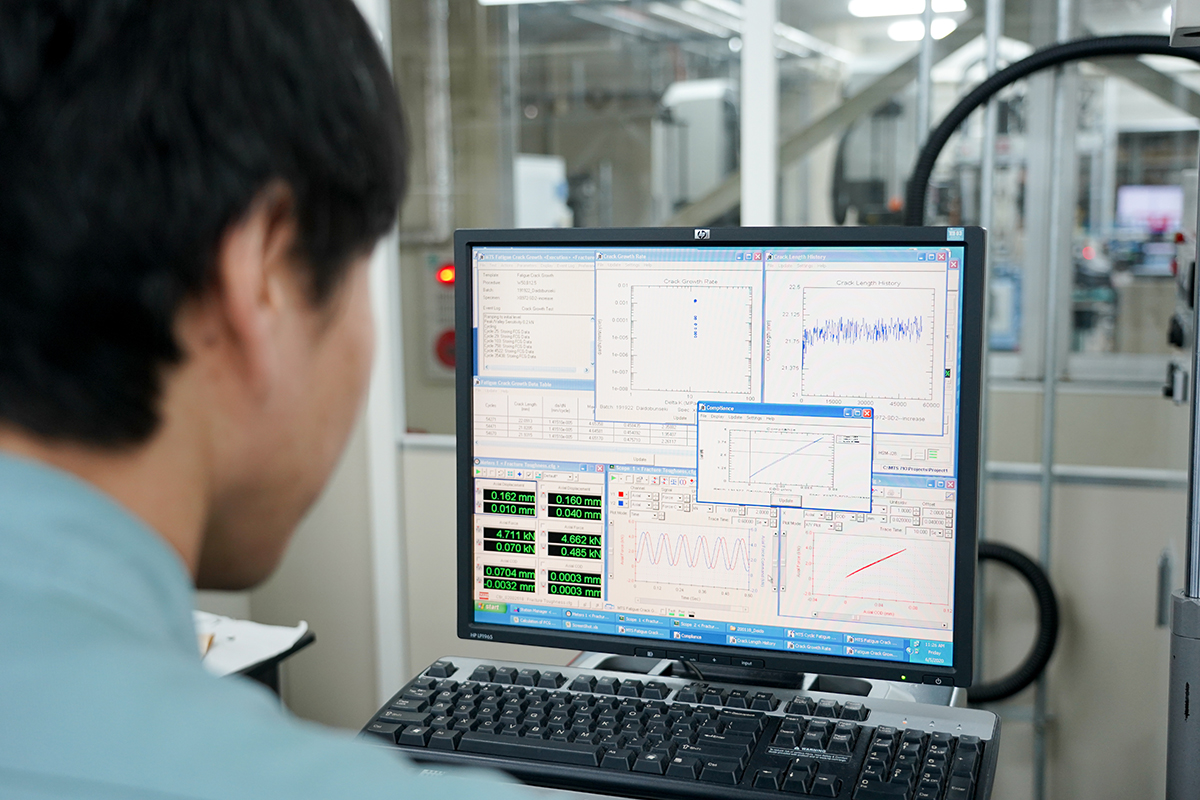

Crack Growth Testing

Crack Growth Testing

Crack growth testing is performed to obtain the relationship between fatigue crack growth rates (da/dN) and stress intensity factor range (ΔK). The tests are calculated the value C and m of Paris Law, and measured the threshold stress intensity factor range (ΔKth).

See details

C (T) specimen is used for large cracks which meets small scale yielding conditions. KB bar specimen is used for small cracks. Cracks can be measured both compliance method and DCPD method.

Testing Standard:ASTM E467 etc.

Environment:Ambient(Further discussion is needed for varying conditions.)

Test Temperature:RT to 900℃(Except for certain temperatures)

Test Machine:MTS 370, MTS 810, etc.

Test Force:3-250[kN]

Measurement of Crack Length:Compliance method, DCPD method, etc.