SERVICE

SPECIMEN PREPARATION (NON-METALS)

Specimen Preparation

Continuously innovating and evolving.

Nonmetallic Materials

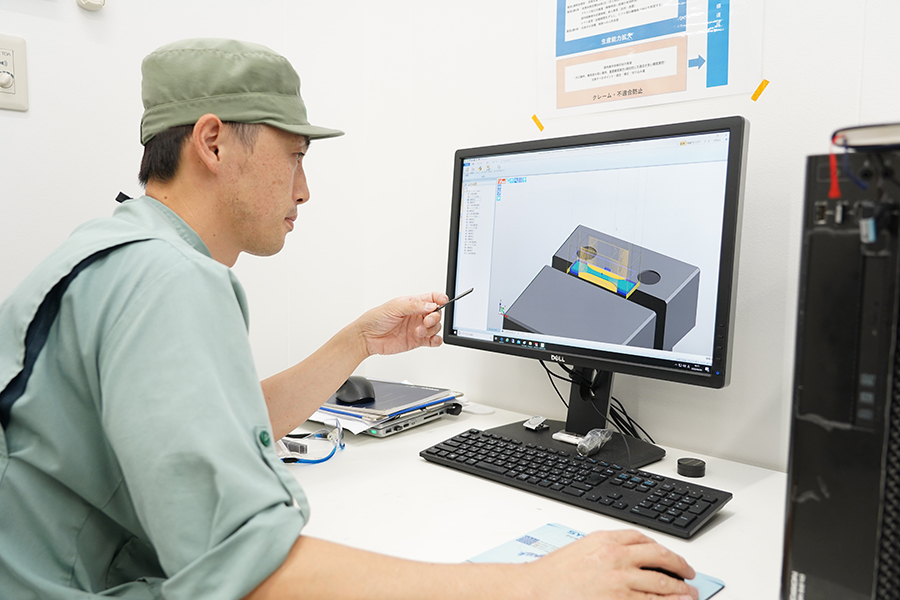

The evolution of CAD/CAM systems makes it possible to create NC programs specific to complicated specimen configurations. To meet machining conditions per material and provide high-quality services, we adopt CAD/CAM systems and prevent human errors.

Programming

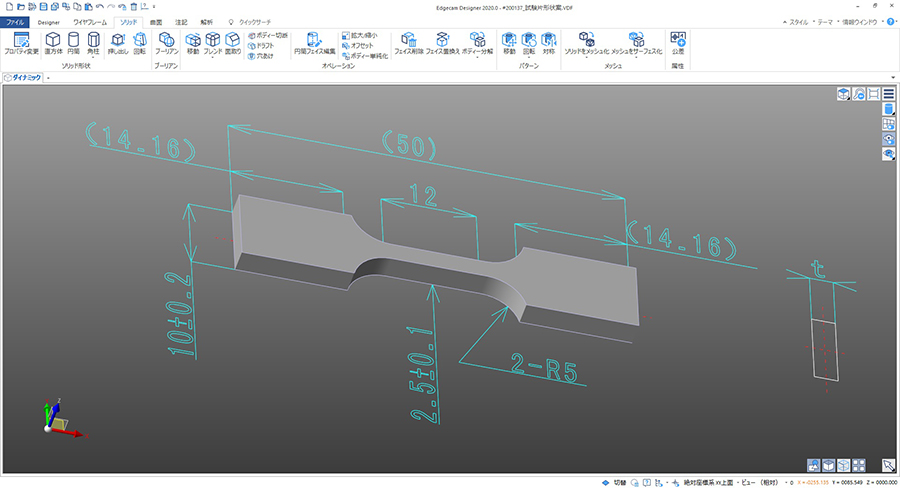

Solid Modeling

Kiguchi Technics consolidates the internal CAD systems and centrally controls specimen drawings. Those pieces of data have a high degree of compatibility with each other, which allows us to create solid models in a few simple steps.

Digitalization of Technologies and Know-how

Kiguchi Technics has received numerous accreditations and approval which require specific technologies and know-how related to specimen preparation. It is important to meet their requirements and we work on building a database to digitalize those technologies and knowledge.

The database usage helps us to automatically create NC programs and simulate a machining process.

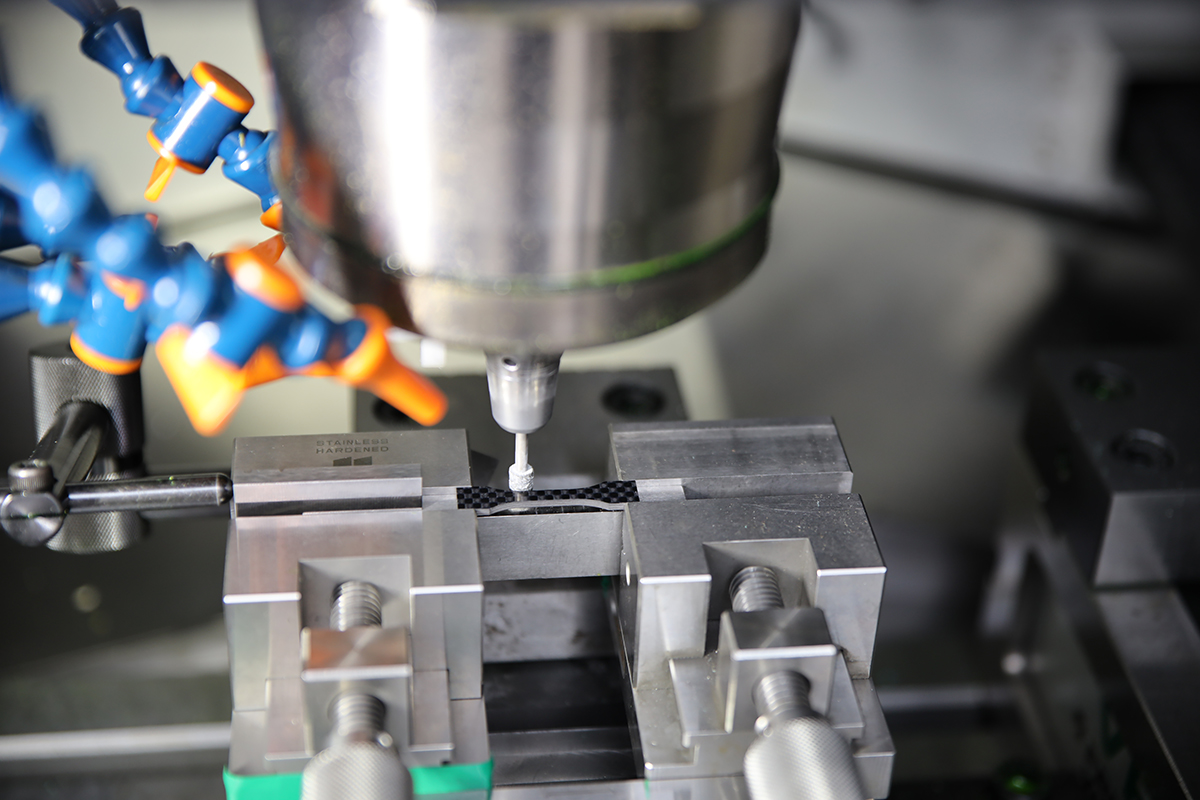

Specimen Machining (Milling Center)

Milling Center

To meet our customers’ needs, we own an ultra high-speed milling center manufactured by Sodick. Tool marks produced during machining operations appear as longitudinal directions on the specimen surface and minimize machining effects as small as possible.

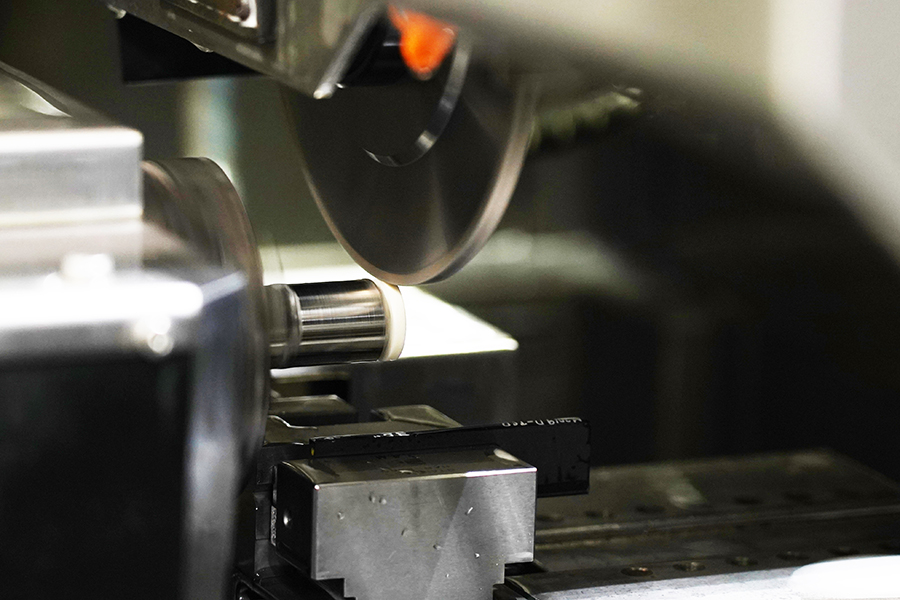

Grinding Process

Surface Grinder

Surface grinding is a process to produce a smooth surface finish by using a grinding wheel. The purpose of this process is to achieve appropriate flatness and parallelism and to minimize any factors affecting test results.

Ultra Precision Micro Profile Grinding Machine

Kiguchi Technics owns multiple micro profile grinding machines with a digital microscope to machine various types of composite materials such as brittle and complex materials.