ABOUT COMPANY

Authorization

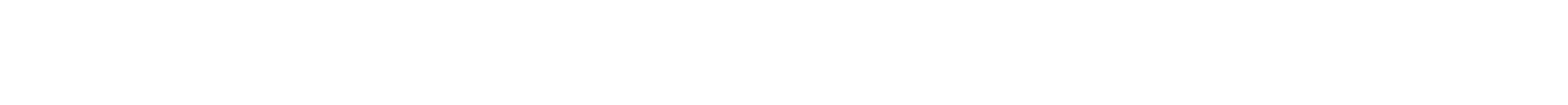

ISO/JIS Q 14001 / Environmental Management Systems

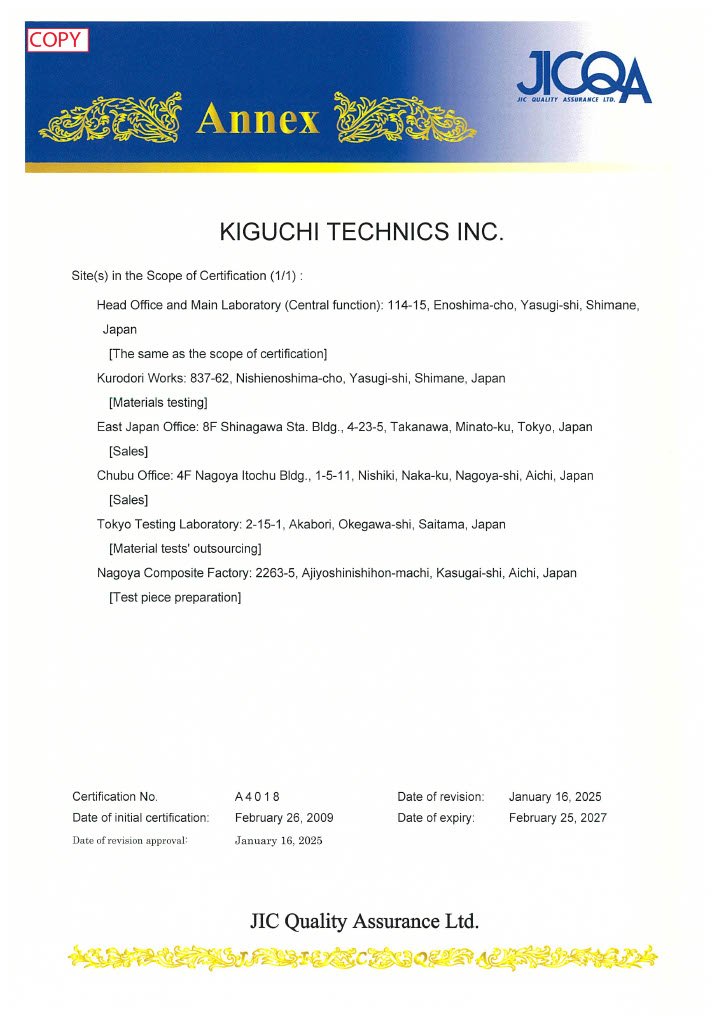

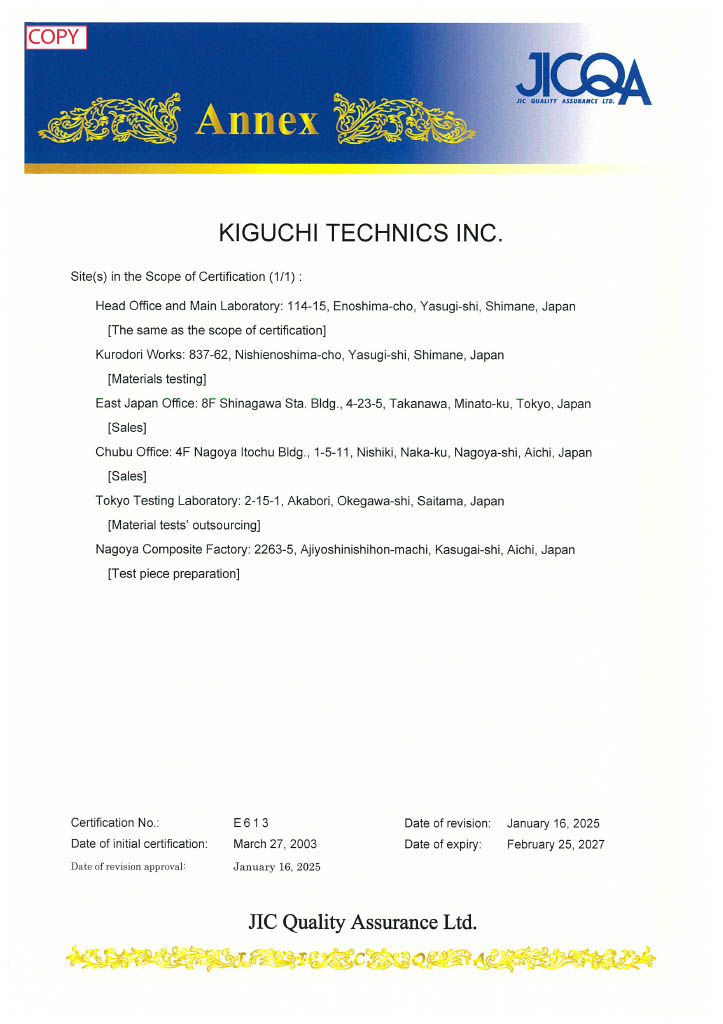

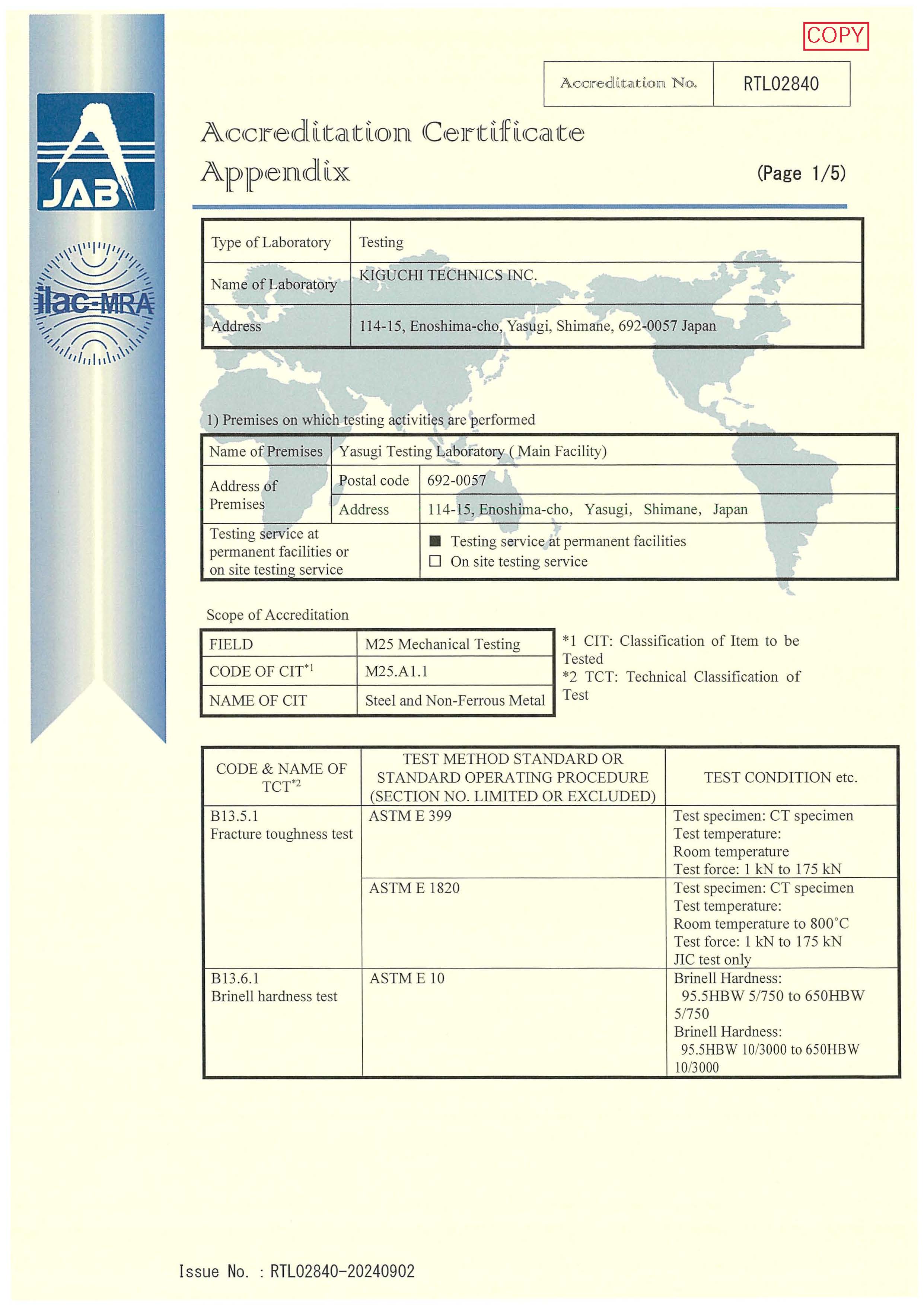

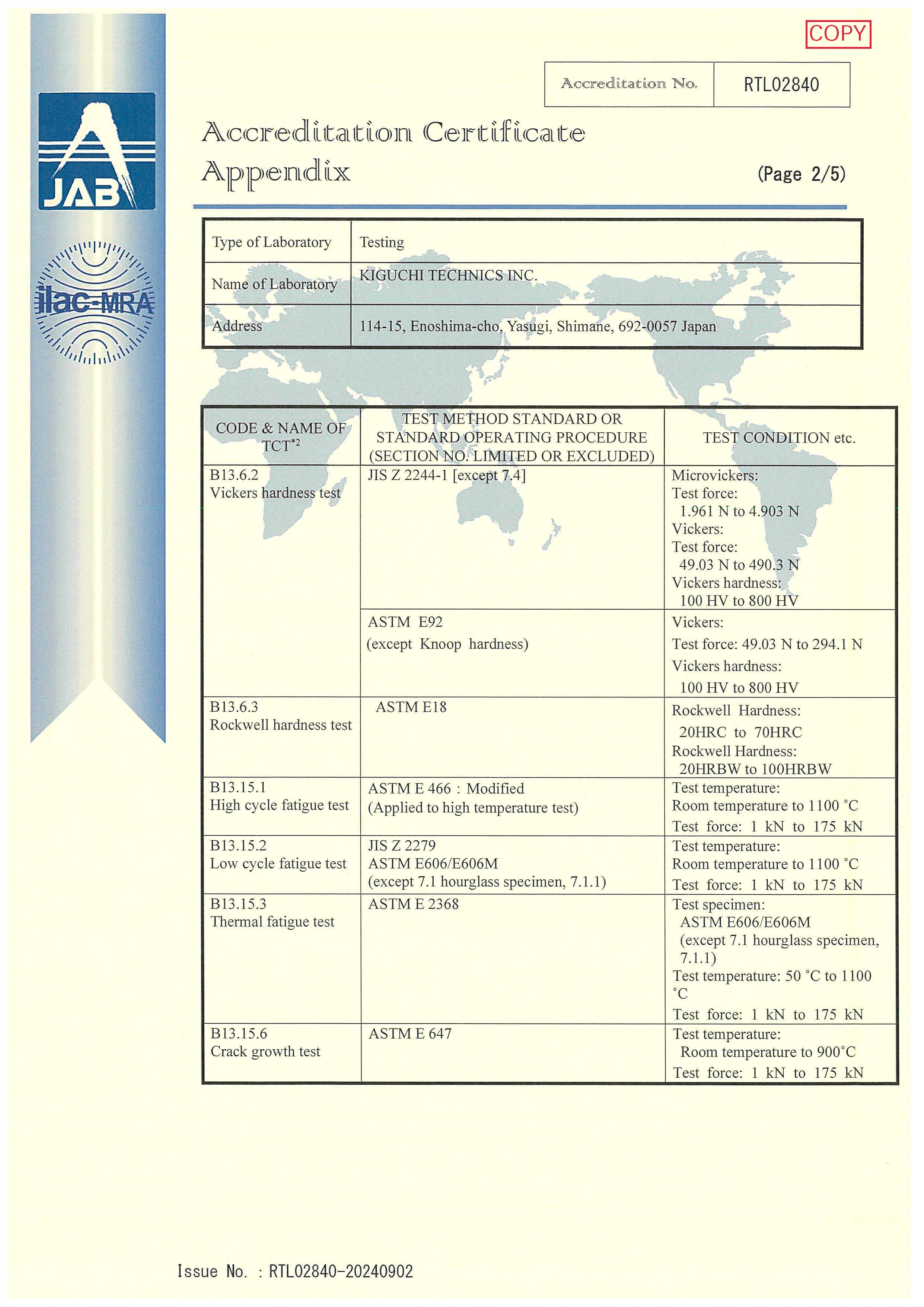

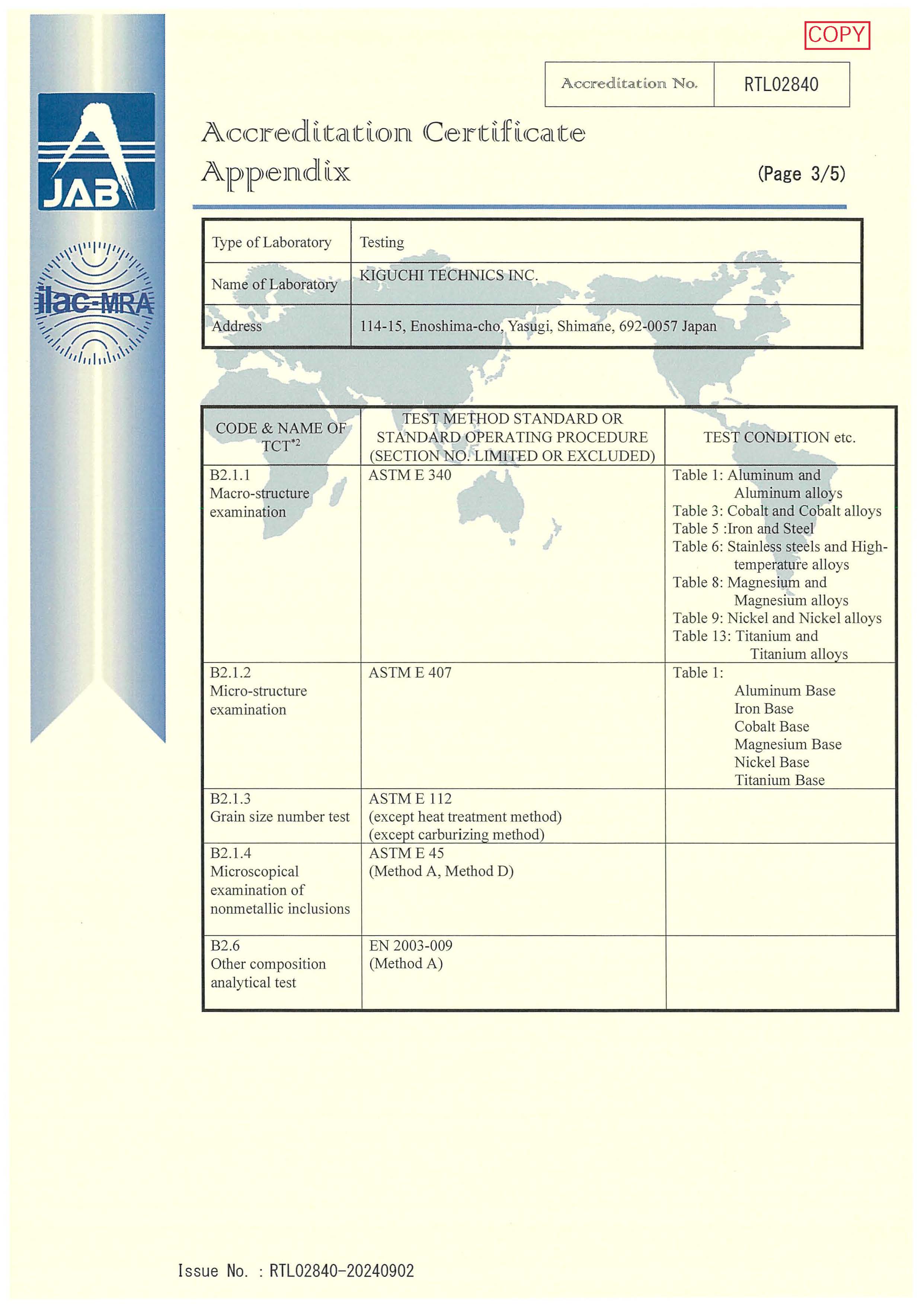

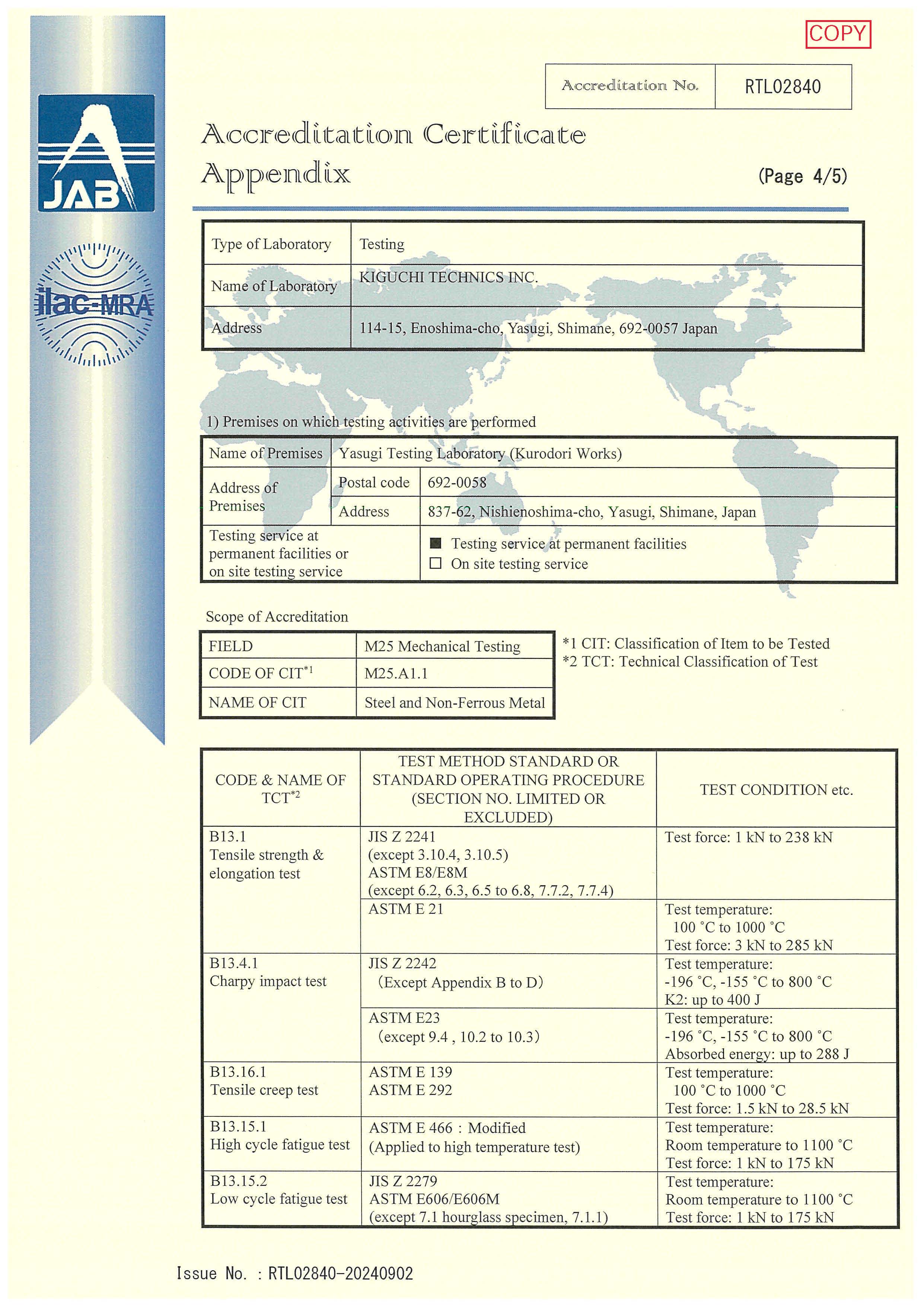

ISO/IEC 17025 (Testing Laboratory) / General requirements for the competence of testing and calibration laboratories

ISO/IEC 17025(Calibration Laboratory) / General requirements for the competence of testing and calibration laboratories

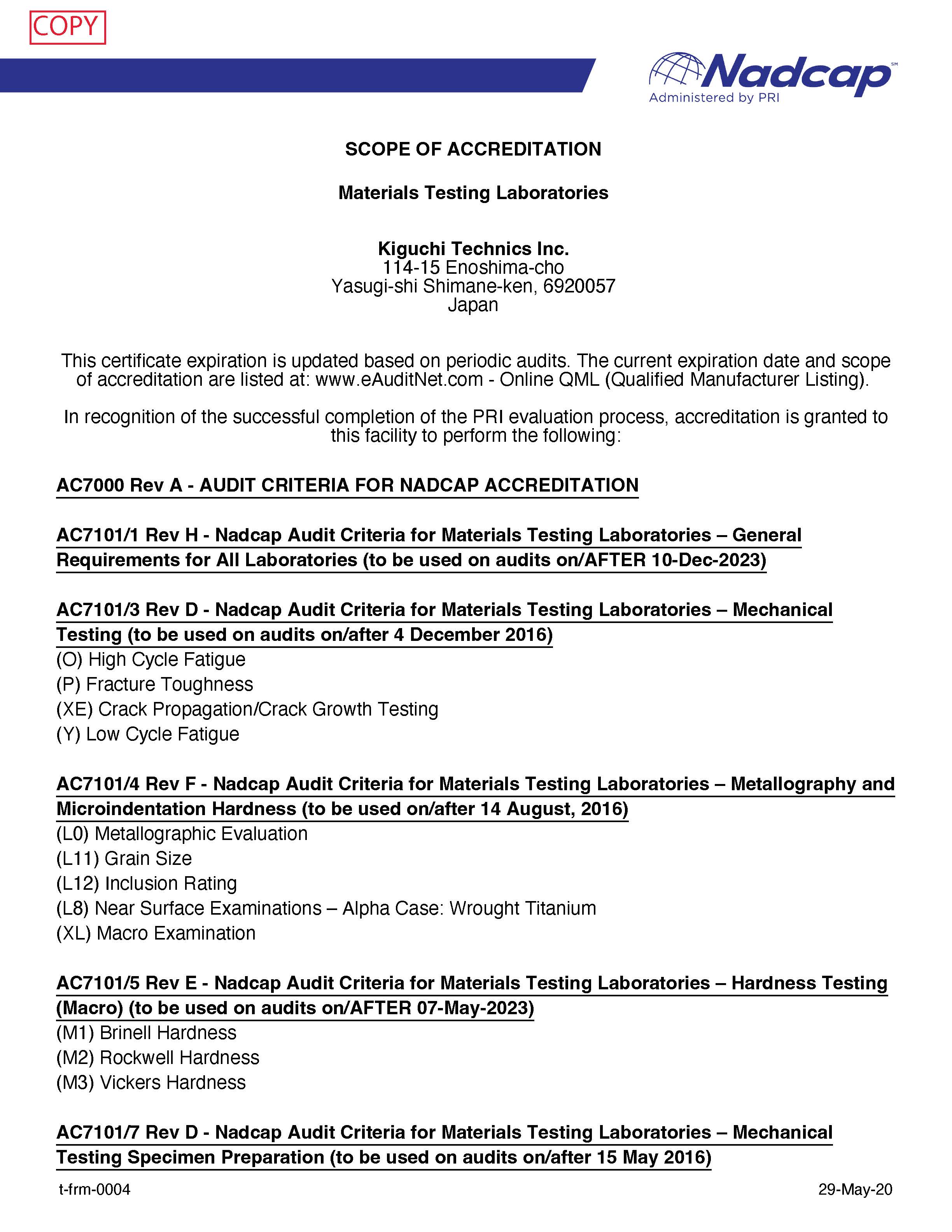

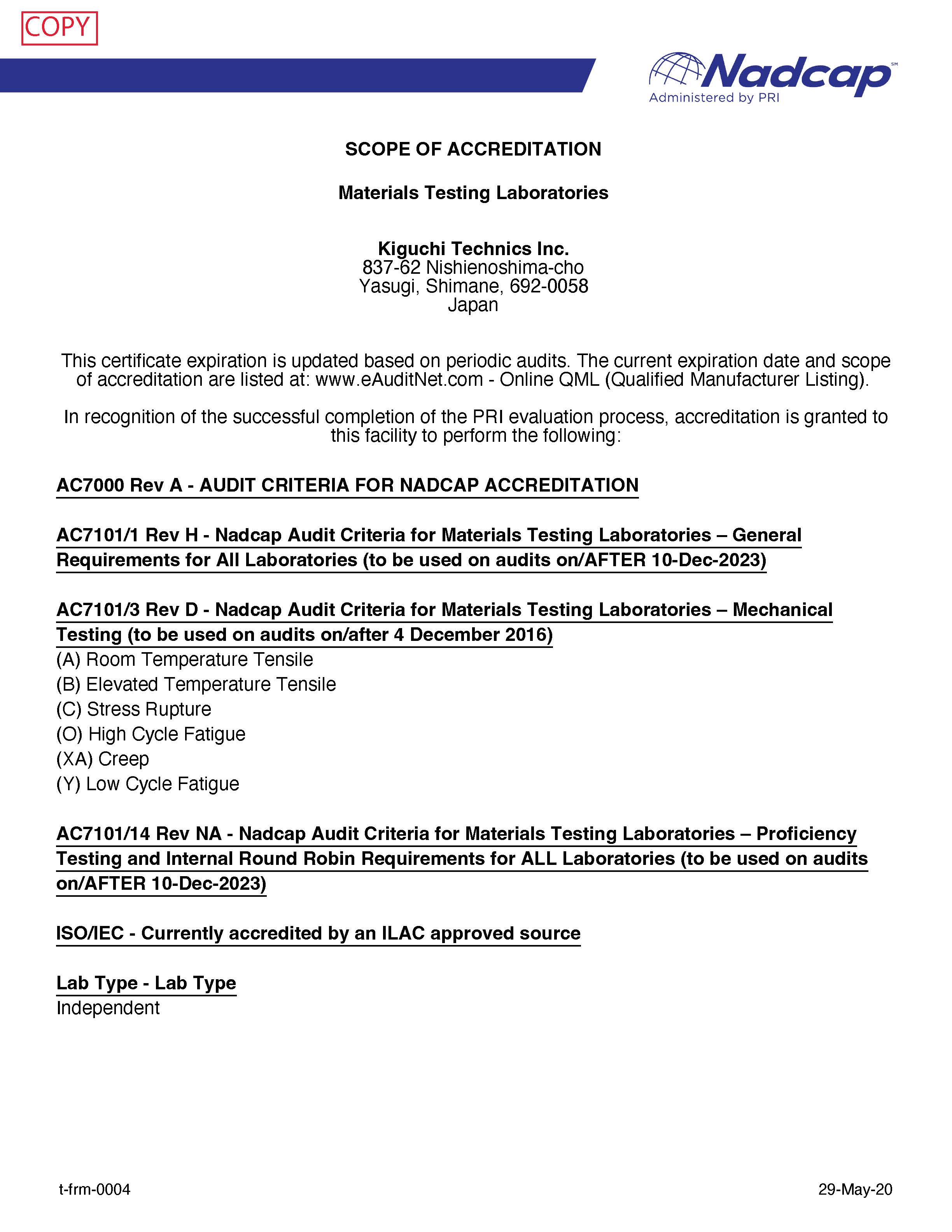

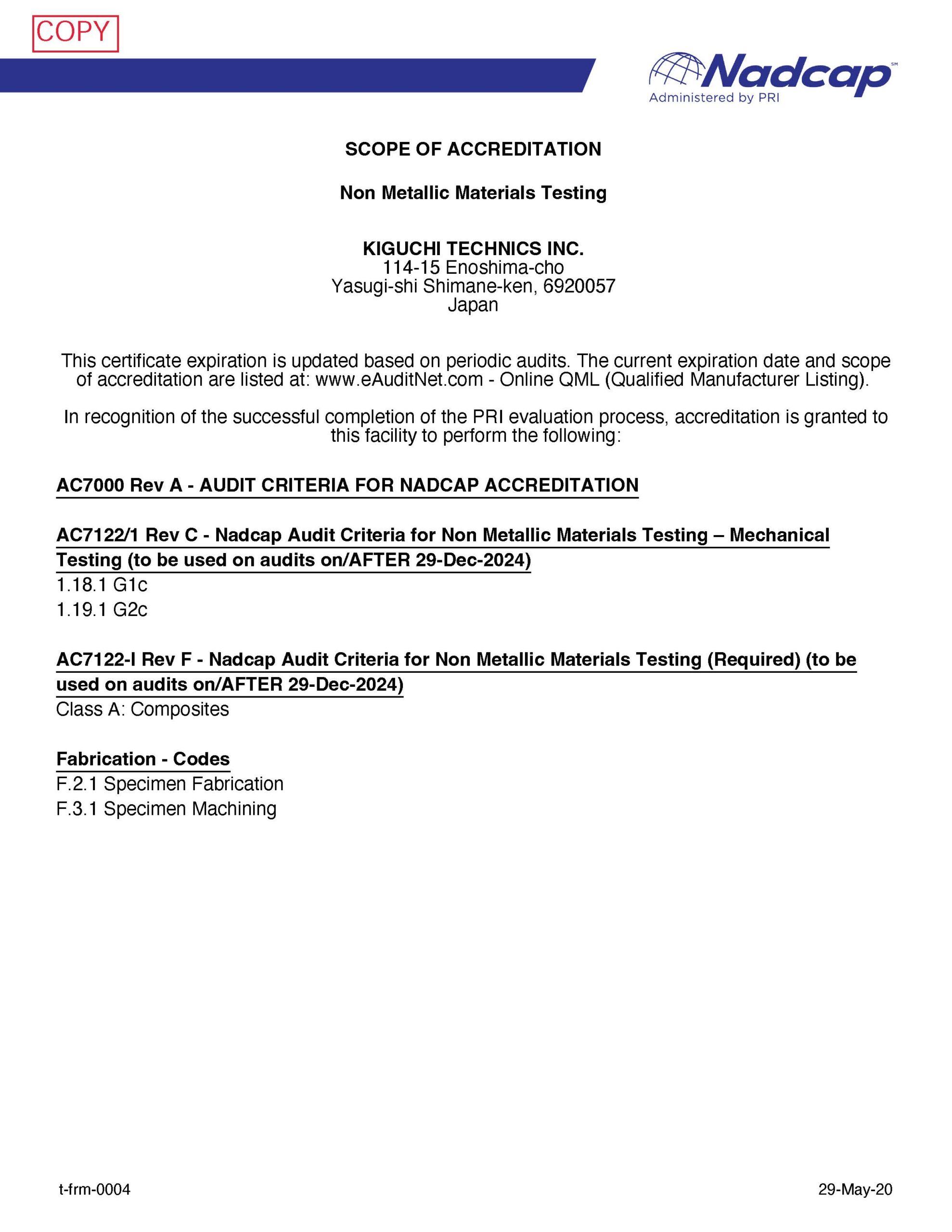

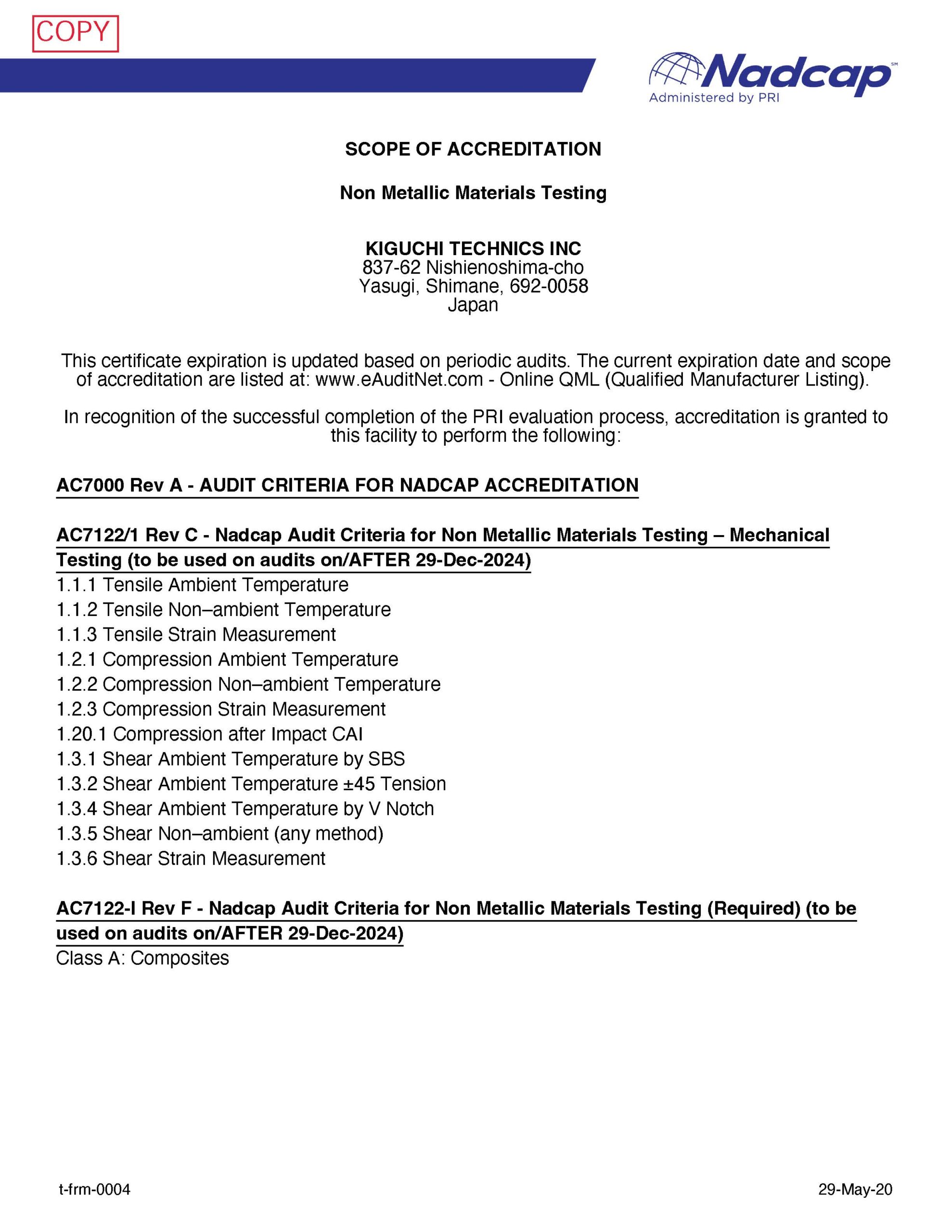

Nadcap(National Aerospace and Defense Contractors Accreditation Program )

Materials Testing (MTL)

Non Metallic Materials Testing (NMMT)

IHI Corporation

| Scope of Approval | Material Testing (J-ISAJT-F005), Metallic Materials Testing (ISAJT-F005) |

|---|---|

| Approval for | Management System |

| Initial App. Date | October 13, 2010 |

| Exp. Date | October 11, 2027 |

| Test Code & Test Item | A: Room Temperature Tensile |

| B: Elevated Temperature Tensile | |

| C: Stress Rupture | |

| L: Metallography (General) | |

| La: Grain Size | |

| L2: Alloy Depletion* | |

| L4: Casting (Mold) Reaction* | |

| L7: IGA/IGO* | |

| L8: Alpha Cace_Wrought | |

| L13: Other* | |

| O: Load Control (High Cycle) Fatigue | |

| P: Fracture Toughness | |

| XA: Creep | |

| XE: Crack Propagation | |

| Y: Strain Control (Low Cycle) Fatigue | |

| Z: Mechanical Testing Specimen Preparation (Low Stress Grinding and Polishing) |

|

| * Applies to ISAJT-F005 ONLY. | |

| Scope of Approval | CMC Materials Testing (ISAJT-F009) |

|---|---|

| Approval for | Management System |

| Initial App. Date | May 10, 2016 |

| Exp. Date | October 11, 2027 |

| Test Code & Test Item | |

| 1A: In-plane Tensile Test (Room Temperature) | |

| 1B: In-plane Tensile Test (Elevated Temperature) | |

| 1C: In-plane Compressive Test (Room Temperature) | |

| 1Ca: In-plane Compressive Test (Elevated Temperature) | |

| 1D: In-plane Shear Test (Room Temperature) | |

| 1E: Interlaminar Shear Test (Room Temperature) | |

| 1Ea: Interlaminar Shear Test (Elevated Temperature) | |

| 1F: Out-of-plane Compressive Test (Room Temperature) | |

| 1Fa: Out-of-plane Compressive Test (Elevated Temperature) | |

| 1G: Out-of-plane Tensile Test (Room Temperature) | |

| 1J: In-plane Tension - Tension Cyclic Fatigue Test | |

| 1N: In-plane Tensile Creep and Creep Rapture Test | |

| 1U: In-plane Shear Test (Elevated Temperature) | |

| 1T: Out-of-plane Tensile Test (Elevated Temperature) | |

| 1V: Out-of-plane Shear Test (Room Temperature) | |

| 1Va: Out-of-plane Shear Test (Elevated Temperature) |

Mitsubishi Heavy Industries, Ltd

| Specification | MSJ4000 |

|---|---|

| Certification Required | AS/EN/JIS Q 9100:2016 |

| Initial App. Date | November 15, 2012 |

| App. Date | May 15, 2025 |

| Exp. Date | - |

| Scope | Activities related to test piece preparation, jig machining, examination services, inspection services, and testing services |

| Item excluded | 8.3 Design and Development of Products and Services |

Kawasaki Heavy Industries, Ltd. Aerospace Systems Co.

| Specification | J-ISAJT-F005 |

|---|---|

| Process | Metallic Materials Testing Laboratories |

| Initial App. Date | July 17, 2013 |

| Exp. Date | October 31, 2027 |

| Test Code & Test Item | A: Room Temperature Tensile |

| B: Elevated Temperature Tensile | |

| C: Stress Rupture | |

| XA: Creep Rupture | |

| O: Force Controlled Fatigue | |

| Y: Strain Controlled Fatigue | |

| L: Metallography | |

| La: Grain Size | |

| L13: Other | |

| Z : Low Stress Grinding of Test Specimens |

| Specification | KQ-7204 |

|---|---|

| Process | Metallic Materials Testing Laboratories |

| Initial App. Date | June 15, 2020 |

| Exp. Date | October 31, 2027 |

| Test Code & Test Item | 1: Room Temperature Tensile |

| 2: Elevated Temperature Tensile | |

| 3: Stress Rupture | |

| 4: Creep, Creep Rupture | |

| 5: Fatigue-Load Controlled | |

| 6: Fatigue-Strain Controlled | |

| 21: Rockwell | |

| 30: General Microstructure | |

| 30-a: Grain Size | |

| 31: Macrostructure | |

| 35*1: Surface Contamination | |

| 70*2: Specimen Heat Treatment | |

| 71: Specimen Machining | |

| 72: Specimen Low-stress Machining |

*1: Applies to Ni, Co, and Fe.

*2: Applies to industrial gas turbine work ONLY as the internal procedures of furnace reference JIS B6901.

GE Aviation

| Scope of Approval | Mechanical Testing, Mechanical Test Specimen Preparation |

|---|---|

| Approval for | S-400 |

| Initial App. Date | October 22, 2014 |

| App. Date | March 18, 2025 |

| Exp. Date | March 31, 2027 |

| Test Code & Test Item | AI0A: Room Temperature Tensile |

| AI0B: Elevated Temperature Tensile | |

| AI0C: Stress Rupture | |

| AI3L: Alpha Case of Wrought Ti Alloys | |

| AI8L: Grain Size | |

| AI9L: Inclusion Content / Other Metallographic Evaluations | |

| AI1M: Rockwell Hardness | |

| AI2M: Brinell Hardness | |

| AI3M: Vickers Hardness | |

| AI0O: High Cycle Fatigue Testing | |

| AI0N: Charpy Testing | |

| AI0P: Fracture Toughness Determination | |

| AI0X: Low Stress Grinding | |

| AI0Y: Low Cycle Fatigue Testing | |

| AI0Z: Low Stress Grinding and Polishing | |

| AIXE: Crack Propagation Measurement | |

| AIXA: Creep | |

| AIXL: Macro Metallography | |

| AIXR: Residual Life | |

| AIXZ: E50TF133 Grain Size Evaluation |

Rolls-Royce

| Scope of Approval |

・Test Piece Machining ・Mechanical testing as specified in CME 5021 and in accordance with RRMS30020 ・RRMS30020 |

|---|---|

| Initial App. Date | October 07, 2015 |

| App. Date | January 03, 2025 |

| Exp. Date | Unlimited |

| Test Item | Tensile (Room Temp. and Elevated Temp.) |

| Stress Rupture | |

| Creep Strain | |

| Low Cycle Fatigue (Load Control / Strain Control) | |

| High Cycle Fatigue (Axial) | |

| Fracture Toughness | |

| Crack Propagation (Compact Tension) | |

| Charpy Impact |

MTU Aero Engines

| Vendor Code | 50000268 |

|---|---|

| Initial App. Date | August 29, 2016 |

| App. Date | July 19, 2024 |

| Exp. Date | July 31, 2027 |

| Test Item | Machining of specimen (Low stress grinding and polishing ) |

| Evaluation of microstructure | |

| RTT-Testing | |

| ETT-Testing | |

| SR Testing | |

| Creep Testing | |

| LCF-Testing | |

| Fracture Toughness | |

| Machining of specimen (Machining of standard specimen ) | |

| Hardness Testing (HBW/HRC/HV) |

Safran Aircraft Engines

| Initial App. Date | June 24, 2014 |

|---|---|

| App. Date | June 12, 2024 |

| Exp. Date | Not limited |

| Test Code & Test Item | Z1: Machining test pieces for metallic fatigue test pieces |

| Z2: Machining test pieces other than metallic fatigue test pieces (such as for tensile and charpy impact tests) |

|

| A: Metals ― Room Temp. Tensile Test | |

| B: Metals ― Elevated Temp. Tensile Test | |

| Y: Metals ― Low Cycle Fatigue Test | |

| O: Metals ― High Cycle Fatigue Test | |

| N: Metals ― Impact Test | |

| M3: Metals ― Rockwell Hardness | |

| L1a: Metals ― Grain Size | |

| L1b: Metals ― Inclusion Content (Except Maraging 250 and ML340) |

|

| L1e: Metals ― Contamination on Ti Alloy (Alpha Case) | |

| XL3: Metals ― Macrographic Examinations | |

| L2a: Metals ― SEM: Fracture Surface Analysis |

Pratt & Whitney

| Scope of Approval | MCL Commercial Lab |

|---|---|

| Initial App. Date | April 9, 2018 |

| App. Date | - |

| Exp. Date | - |

| Test Code & Test Item | 1: Tensile (Room Temp.) |

| 2: Tensile (Elevated Temp.) | |

| 3: Stress Rupture | |

| 4: Creep Strain | |

| 5: Hardness (Brinell and Rockwell) | |

| 7: Metallographic Examination | |

| 7a: Microstructure/Grainsize | |

| 7h: Heat Treat (Only test for heat-treated specimens) |