SERVICE

SPECIMEN PREPARATION (METALS)

Blanking

Continuously innovating and evolving.

Material Cut-up

Kiguchi Technics uses a variety of cutting techniques such as band saws, wire EDM, and waterjet processes to cut up difficult-to-cut and large-sized materials.

Blanking Location

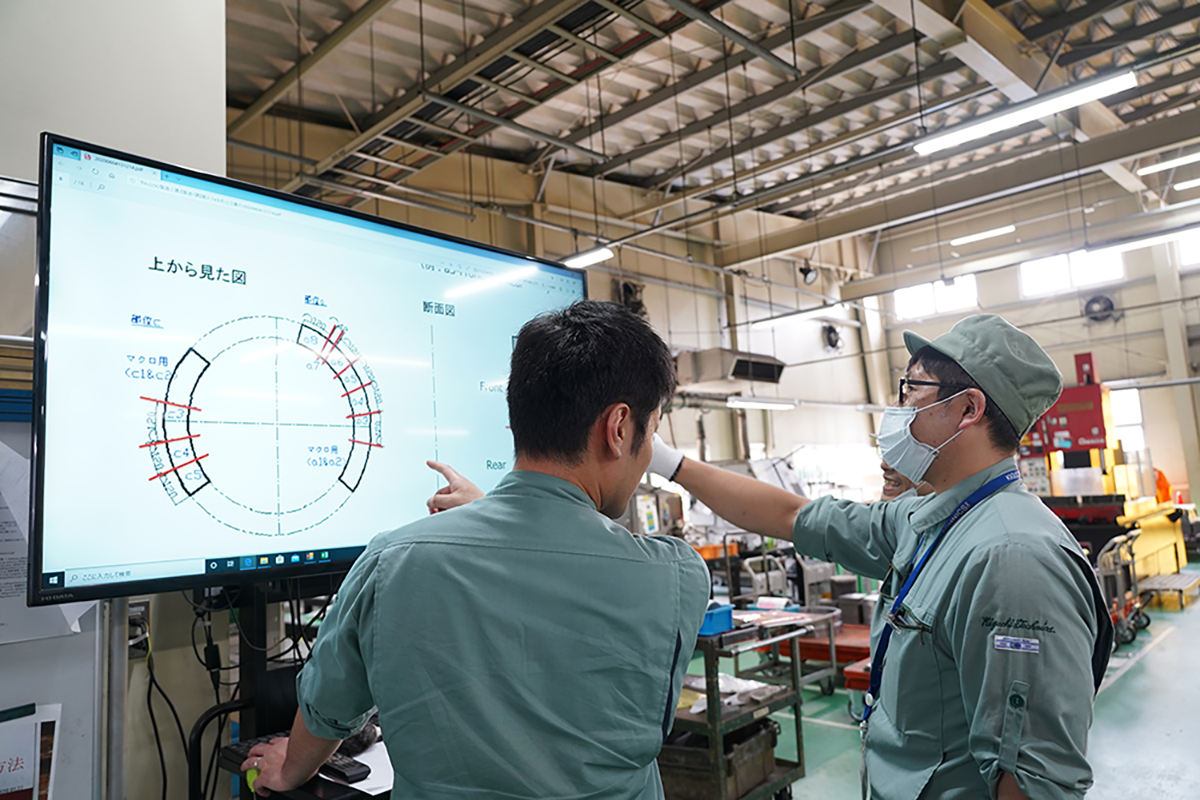

Digitalization of Paper-based Documentation

For the progress of IT and ICT, we are working to digitize paper-based documentation. A display such as digital signage is installed in each facility to check the latest information about specimens and identify blanking location.

Equipment

It is important to select the most appropriate equipment for cutting operations to suit the size, configuration, and features of supplied materials.

Marking

Prior to taking test samples from a material, we outline marking locations. Recording of marking locations is necessary as proof to maintain our established standards of quality.

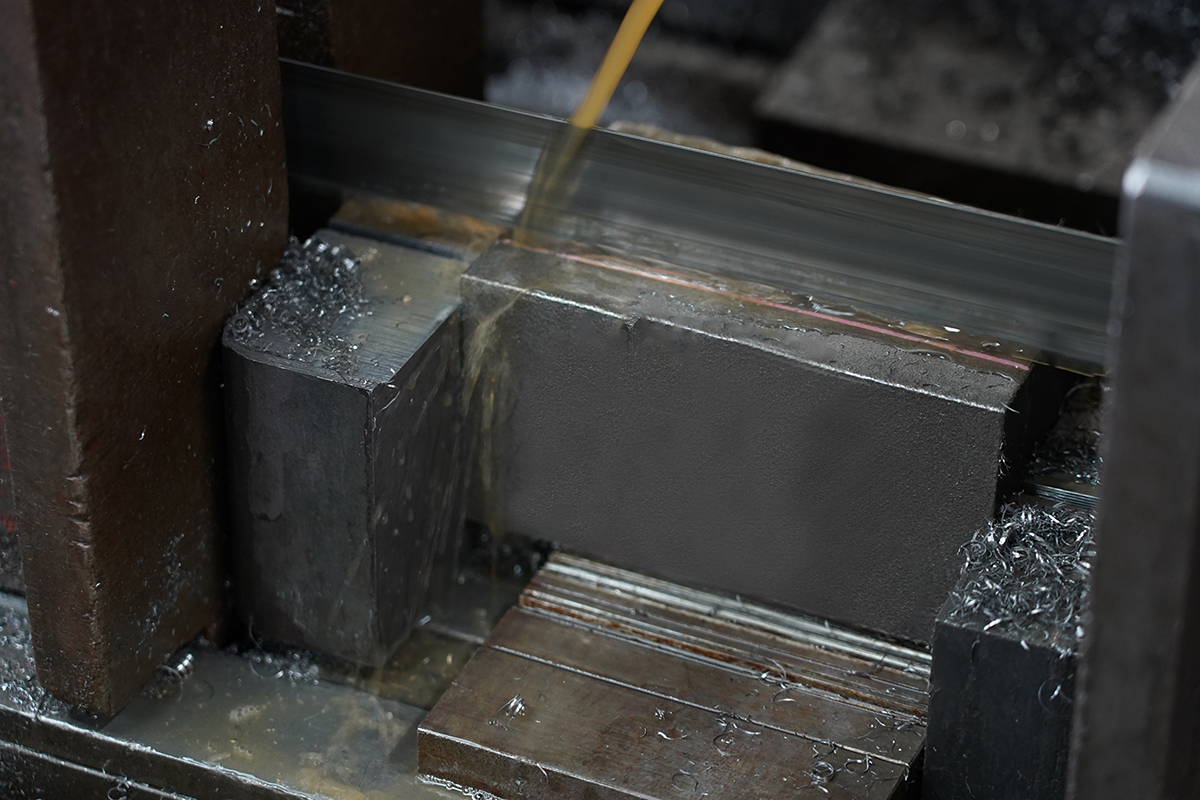

Blanking Operation

Band Saw

Our machine shop owns the following machines manufactured by AMADA to cut large-sized materials: vertical band saw machines such as the models of VM-420, VM-1200, and VM-3800, and horizontal band saw machines such as H and HA/HFA series.

Cutting Tools

For band saw cutting process, it is important to select the band saw blade to suit the size, configuration, and features of supplied materials.

We own multiple cutting machines and band saw blades so as to offer an appropriate cutting plan to our customers with cost-effectiveness.

Automated Service

To raise operation rates and build an efficient production system, an operation sensor is installed in each machine (e.g. manual and NC machines) and connected to our internal networks.

This system enables us to monitor the operational status of the machines correctly and in real-time.

Wire Electrical Discharge Machine (Wire EDM)

Kiguchi Technics has multiple wire EDMs manufactured by Mitsubishi Electric Mechatronics Engineering Corporation. For large-sized materials, some of the models, such as FA50V and MP4800, are used to meet customers’ needs for fast delivery and accurate operation.

Also, work environment temperature control, periodic maintenance by manufacturers, and the usage of large-sized wires enable a long-term operation of the machines.

Large-sized Materials

We built the new facility in April 2019 to establish an environment in which large-sized materials can be smoothly received.

In this facility, the wire EDMs allow us to work difficult-to-cut materials.

24-hour Operation

Cutting large-sized materials needs long-term machine operation. The operation sensor installed in each machine is connected to the internal networks to support the data transfer, real-time monitoring, and early detection of troubles.