SERVICE

Specimen Preparation (Metals)

Dimension Inspection

Continuously innovating and evolving.

Specimen Dimension

Kiguchi Technics performs 100% inspection for specimen appearance with appropriate measuring instruments to ensure that specimen dimensions measured meet customers’ requirements. Measuring instruments owned by Kiguchi satisfy the ISO/IEC17025 requirements and they are calibrated by a calibration agency traceable to the national measurement standards. Those calibrated measuring instruments are controlled with a certificate having the mark of conformity.

Contact Measurement

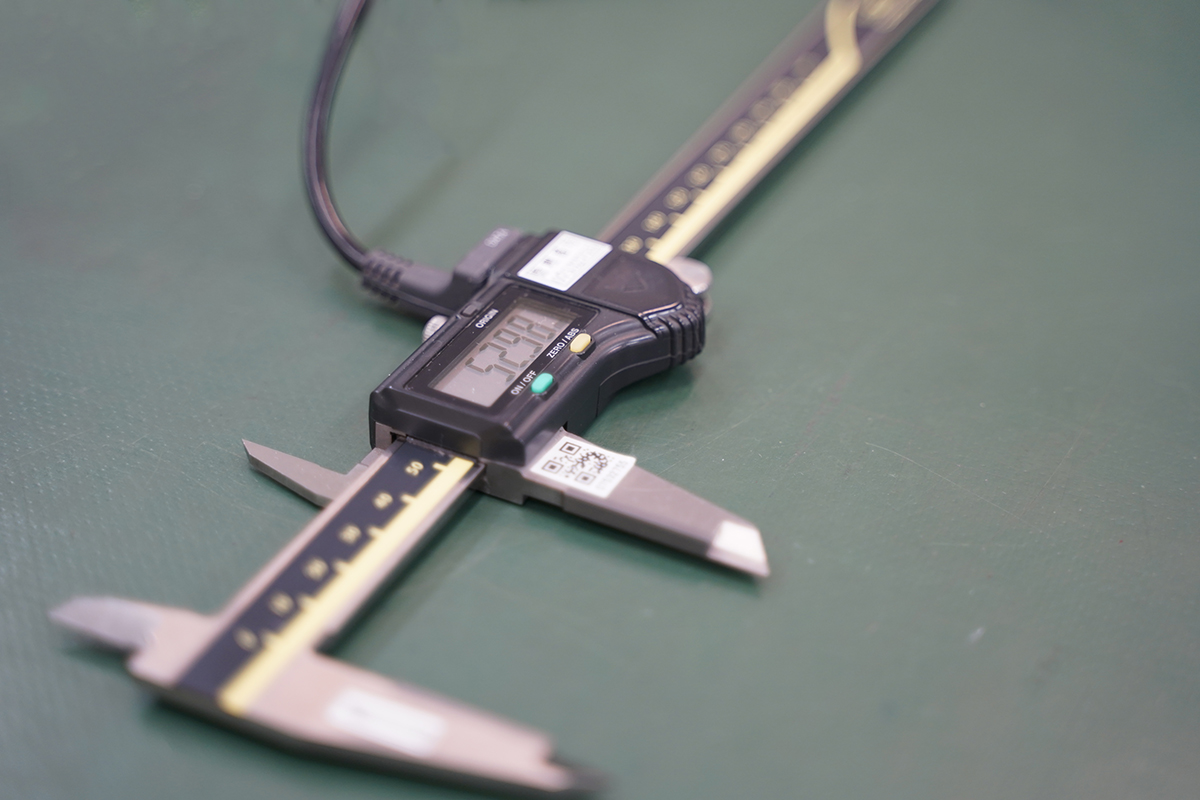

Micrometers and Calipers

Measuring with a micrometer or caliper varies between individual inspectors. To establish the validity of each measurement, we periodically assess the competence of each inspector to meet the internal criteria.

Dimension Inspection Data

Almost all of the measuring instruments owned by Kiguchi are capable of directly transmitting measurement data to a digital certificate. The data transmission systems help us to prevent human errors and reduce stress for inspectors.

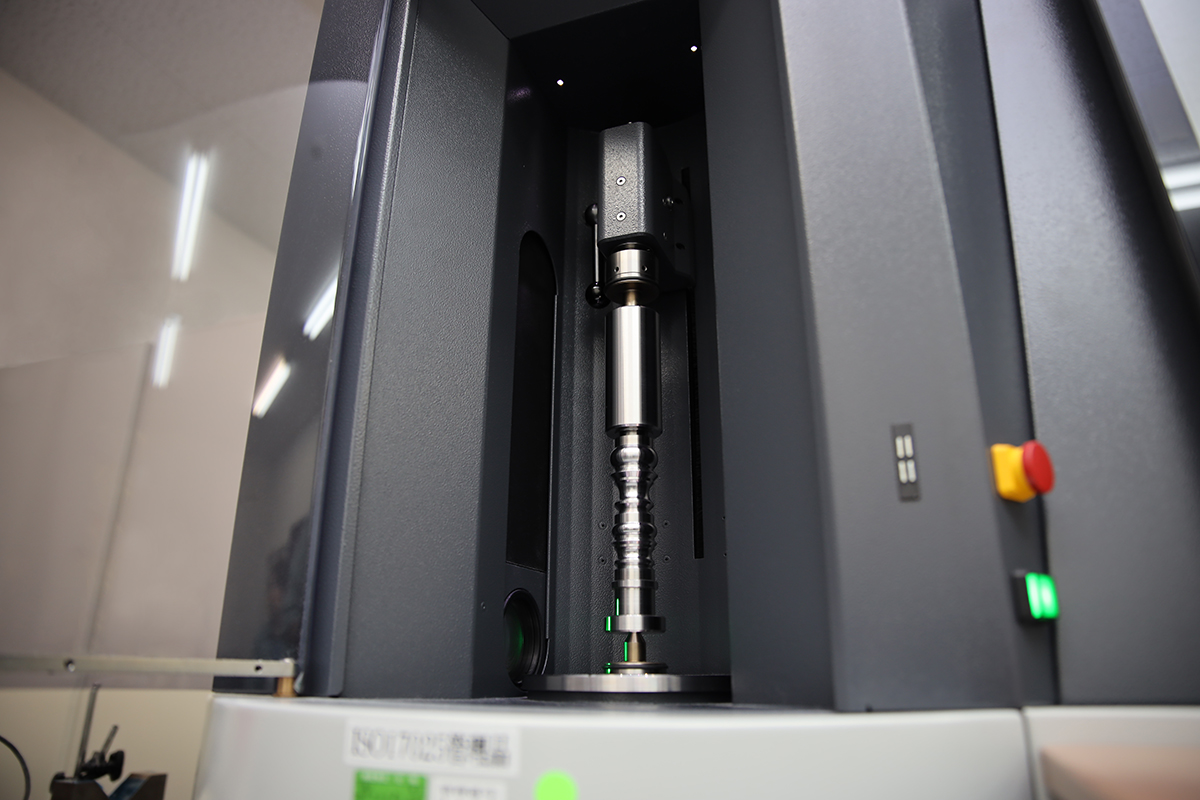

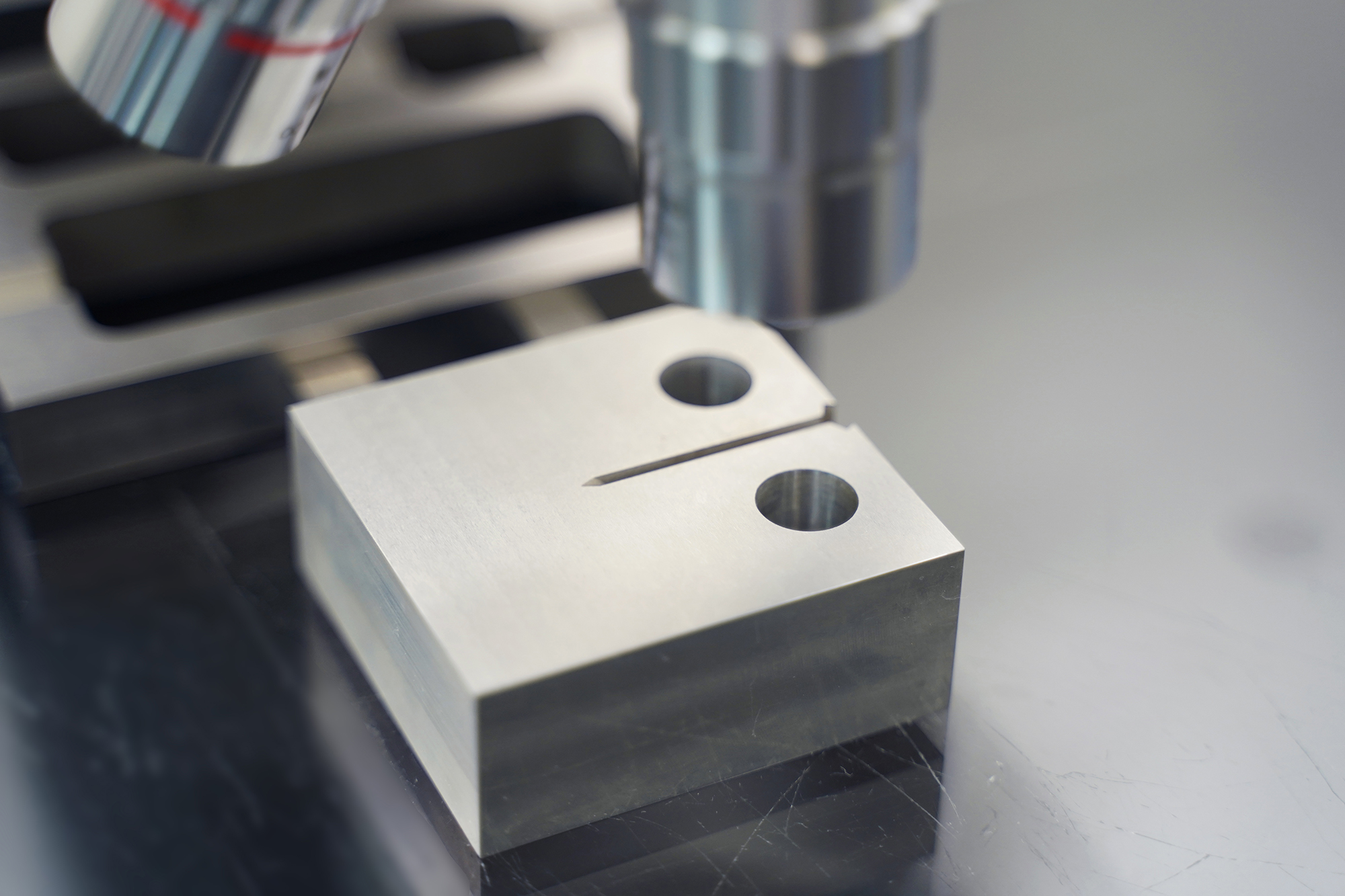

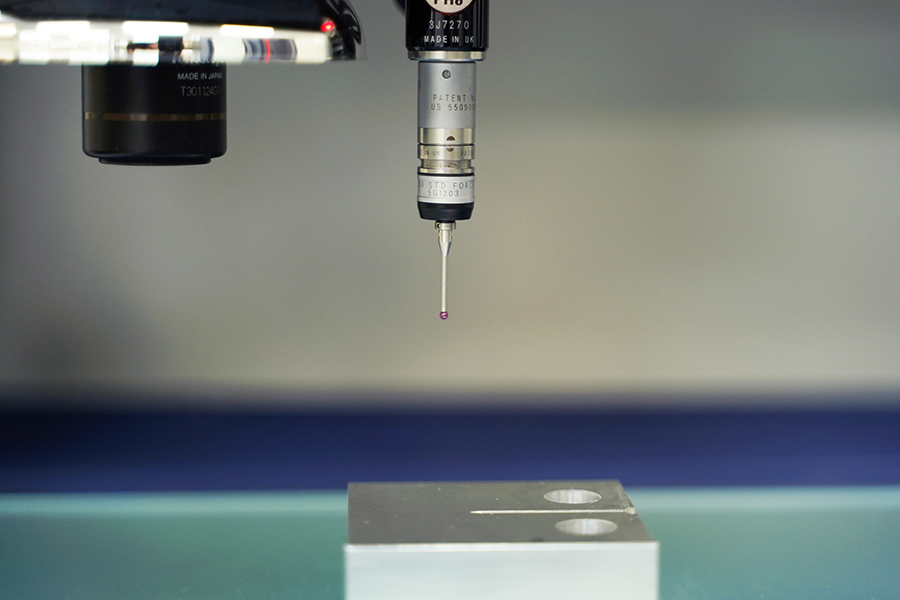

Coordinate-measuring Machine

Coordinate-measuring Machine

A coordinate-measuring machine is a device that measures specimen geometry by sensing discrete points on the surface of specimens with a probe. This machine enables us to measure complex geometry of fixtures. For a given geometry, we can set up programs for automatic measurements.

Probe to be Used for Measurement

We own multiple probes to measure various types of geometry of specimens and fixtures.

Optical Measurement

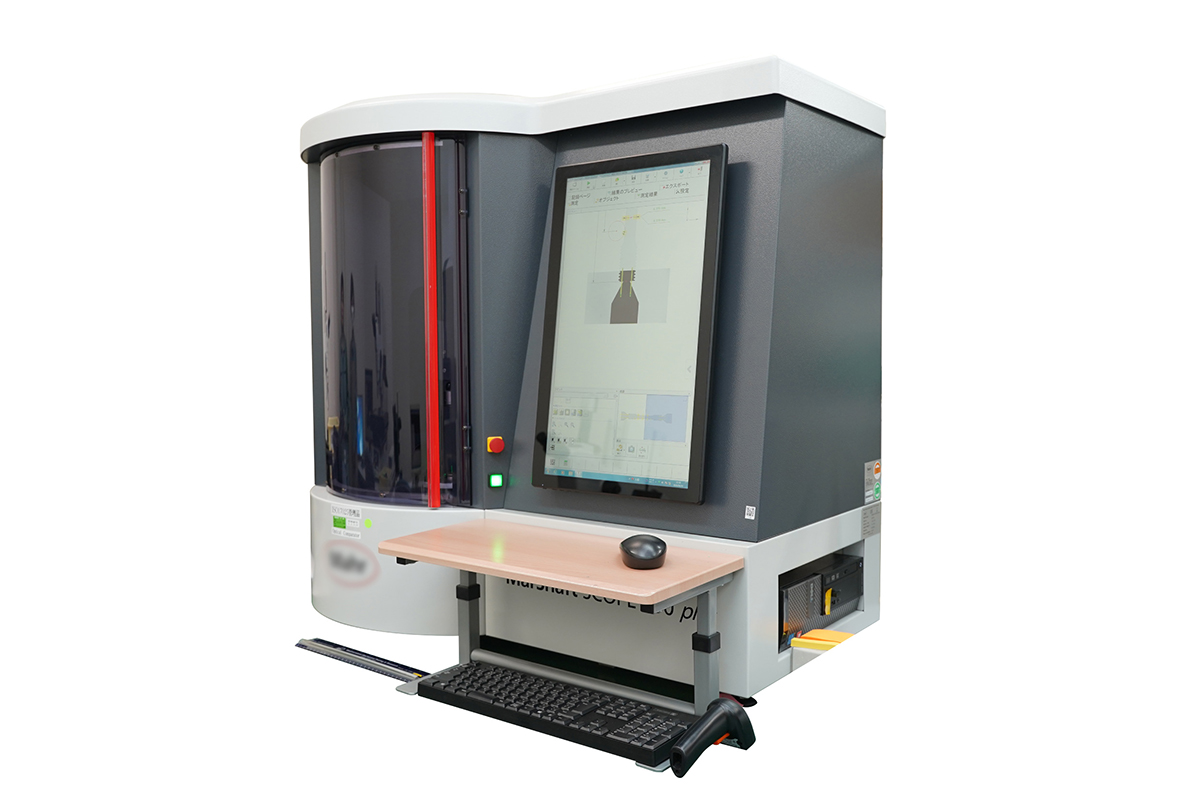

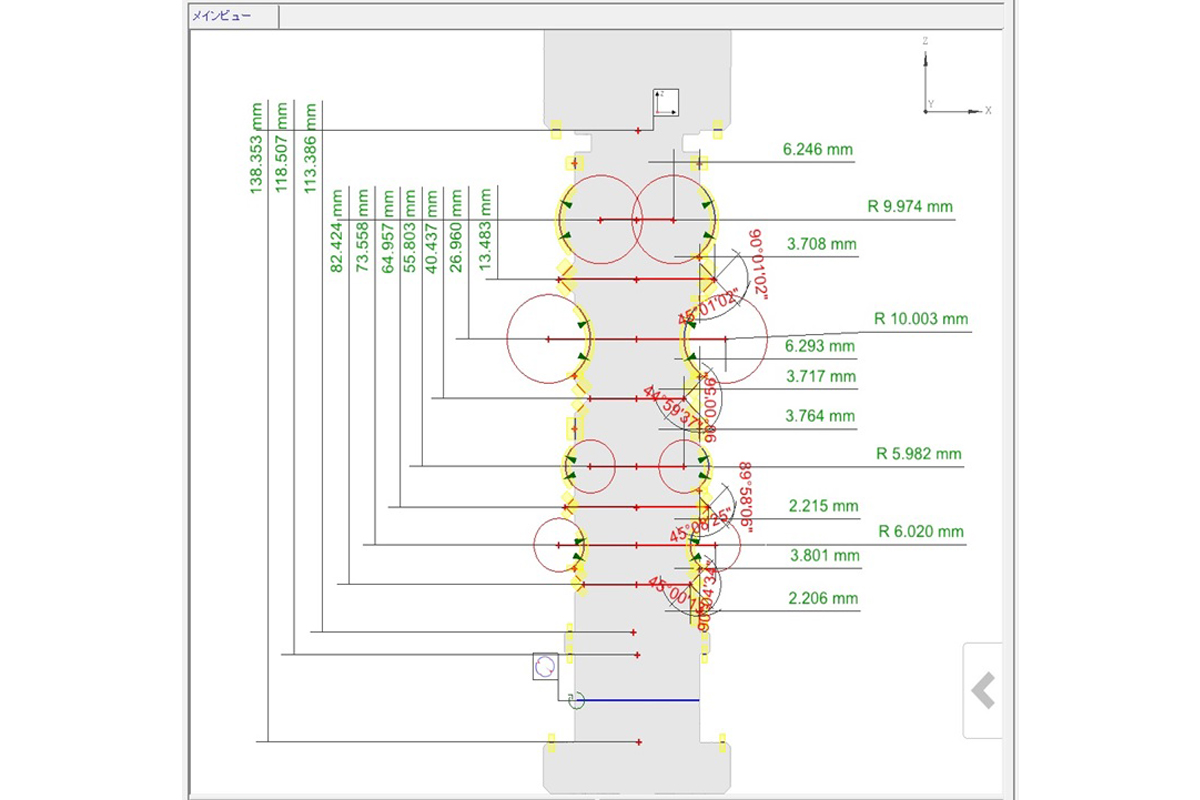

Optical Measuring System

For cylindrical specimens, optical measuring systems such as optical comparators make it possible to set up programs for measuring locations prior to measurements. Thanks to this, specimen dimensions can be automatically measured, which brings time-saving in inspection processes. The usage of specimen drawings created by CAD systems enables us to prepare measuring programs with another system and to realize continuous measurements without any delay.

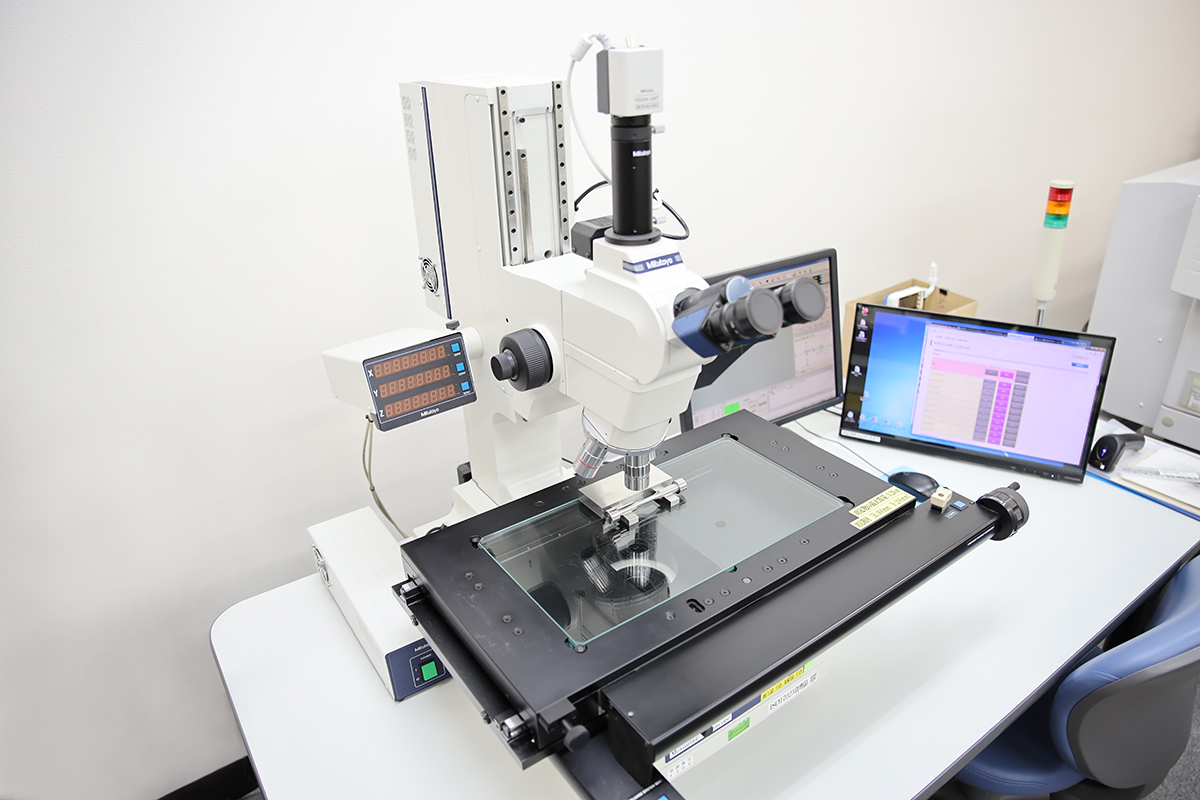

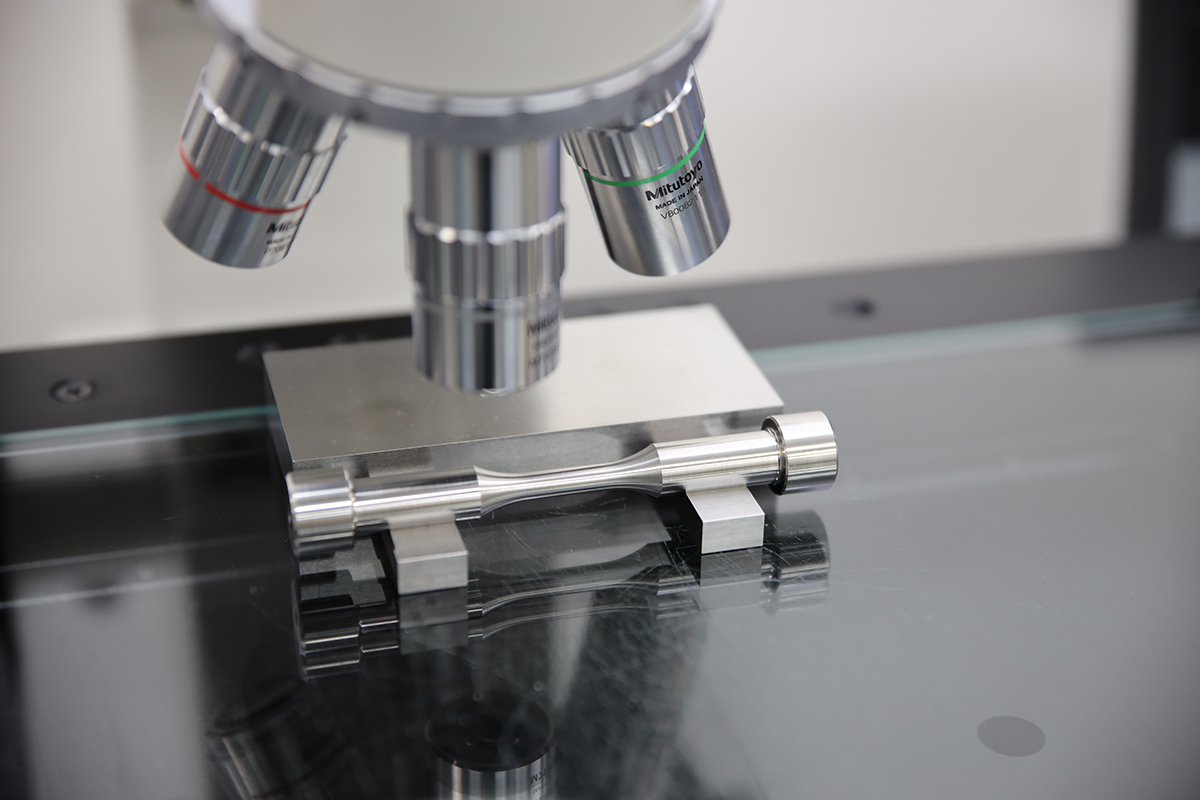

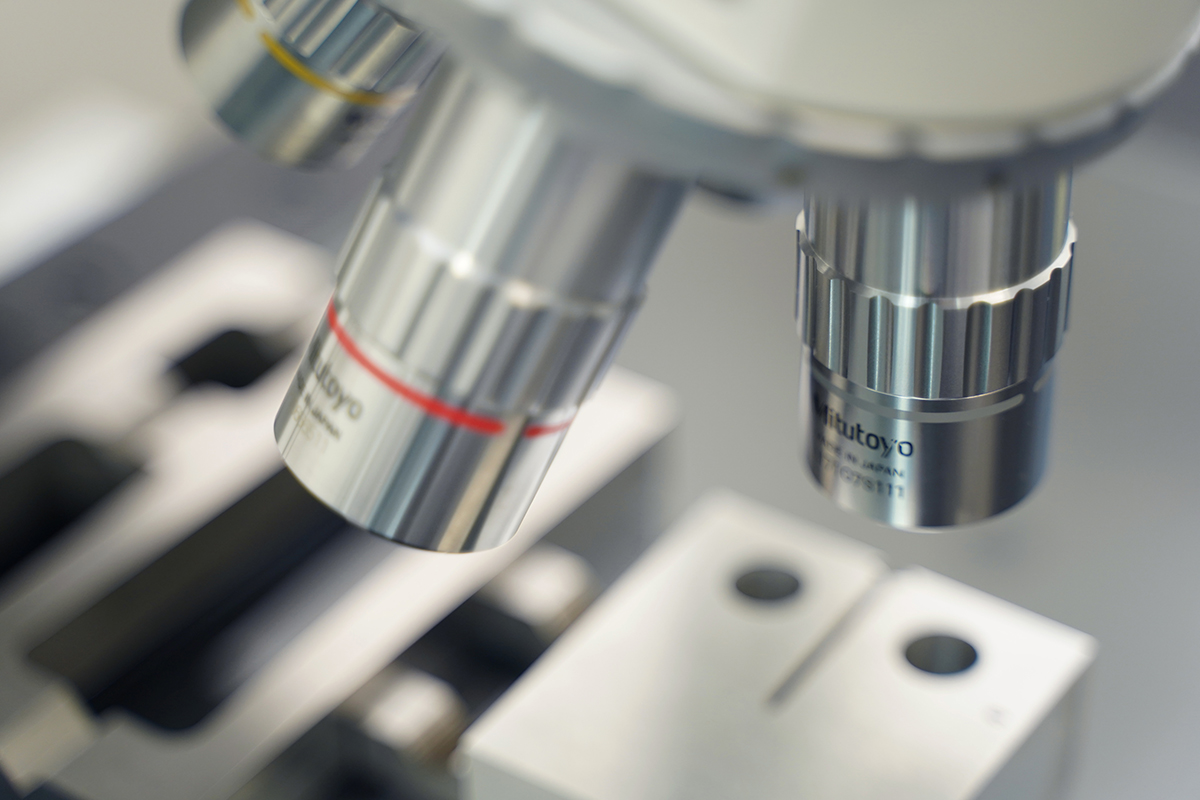

Measuring Microscope

A measuring microscope is used for dimensional measurements by adjusting each magnification and observing appropriate fields of specimens. Upon our customers’ request, we perform an inspection before and/or after testing.

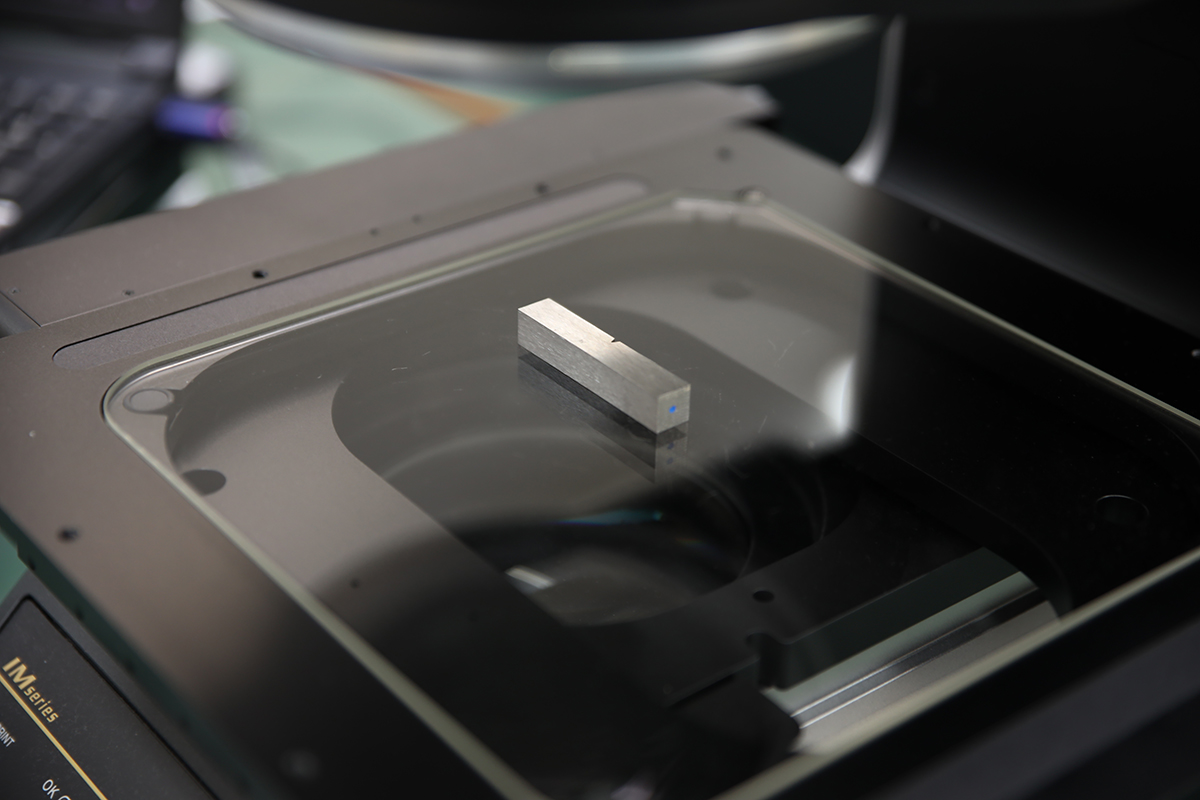

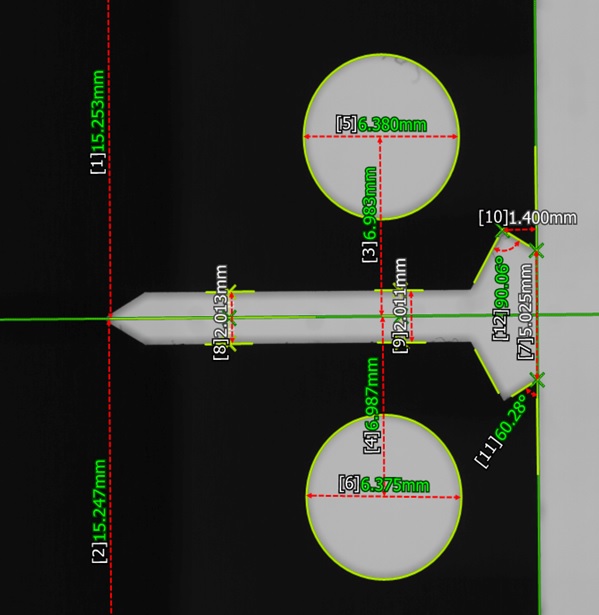

Image Dimension Measuring System

To measure various types of specimen configurations such as flat and cylindrical specimens, we use an image dimension measuring system and set up programs to automatically measure several dimensions of a specimen at the same time.

Laser Measurement

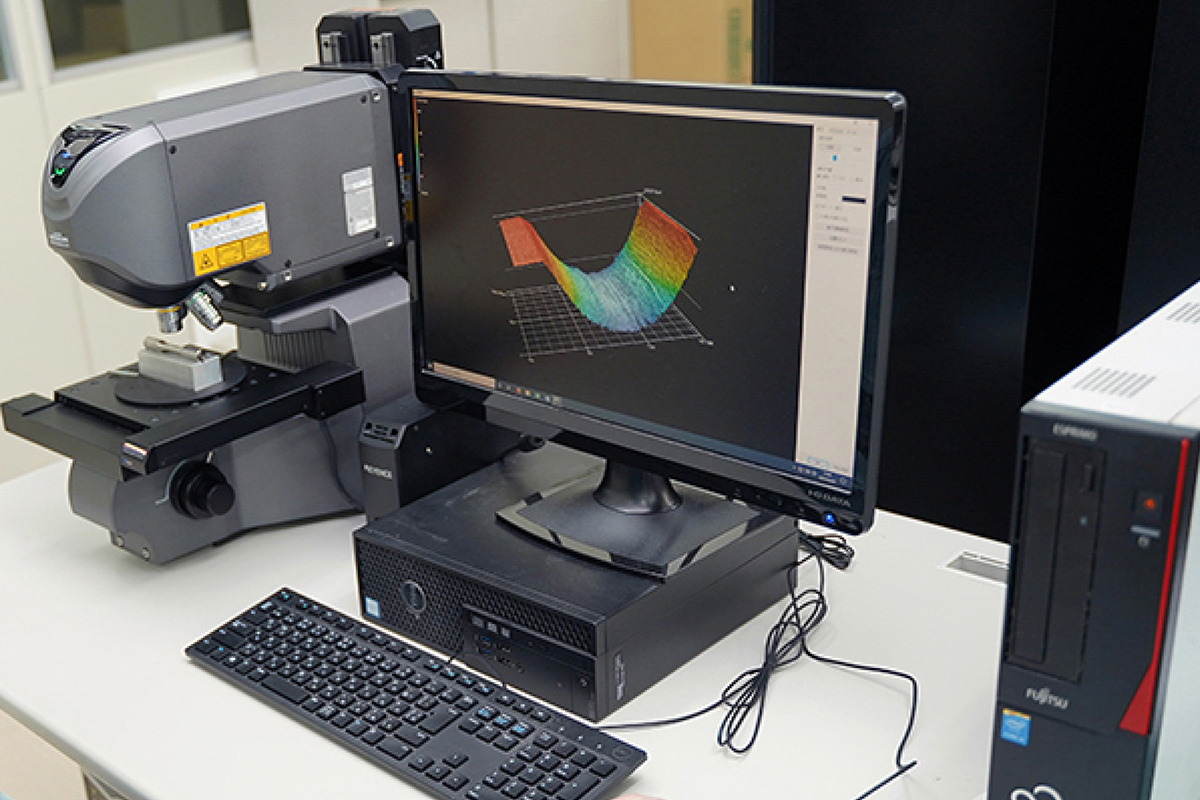

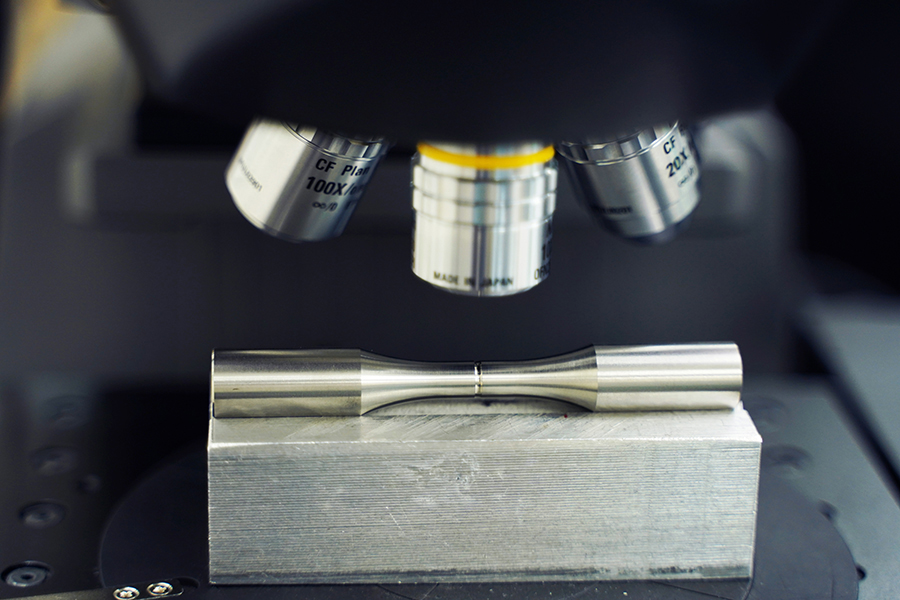

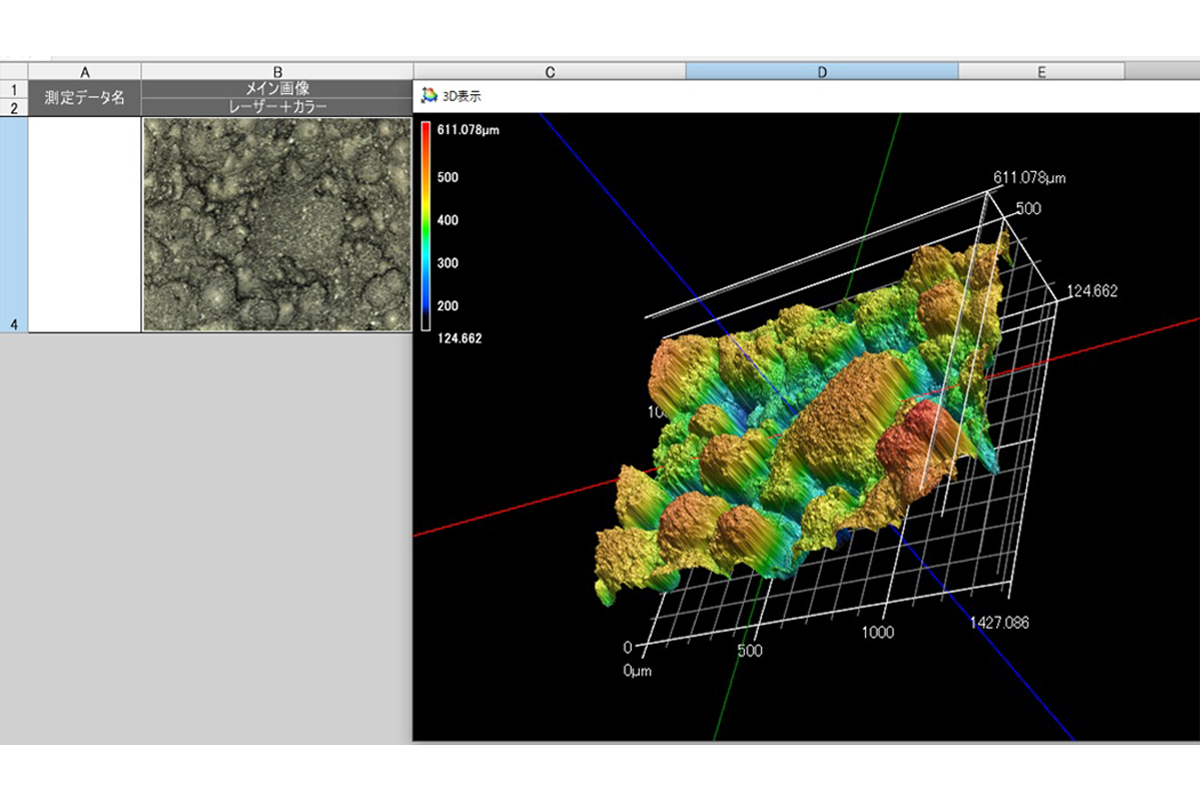

Laser-scanning Microscope

A laser-scanning microscope is a non-contact measuring instrument for surface roughness/profile measurements. Measurement results can be analyzed by 3D images to check surface roughness/profile visually.